Achieve up to 15% reduction, streamlining processes and maximizing output.

Witness a whopping 50% increase in Mean Time Between Failures, ensuring machines work longer and harder.

Reduce set-up and transition times by an impressive 20%.

GO PAPERLESS!

Opt for a greener, efficient, and less cluttered workspace with our paper reduction features.

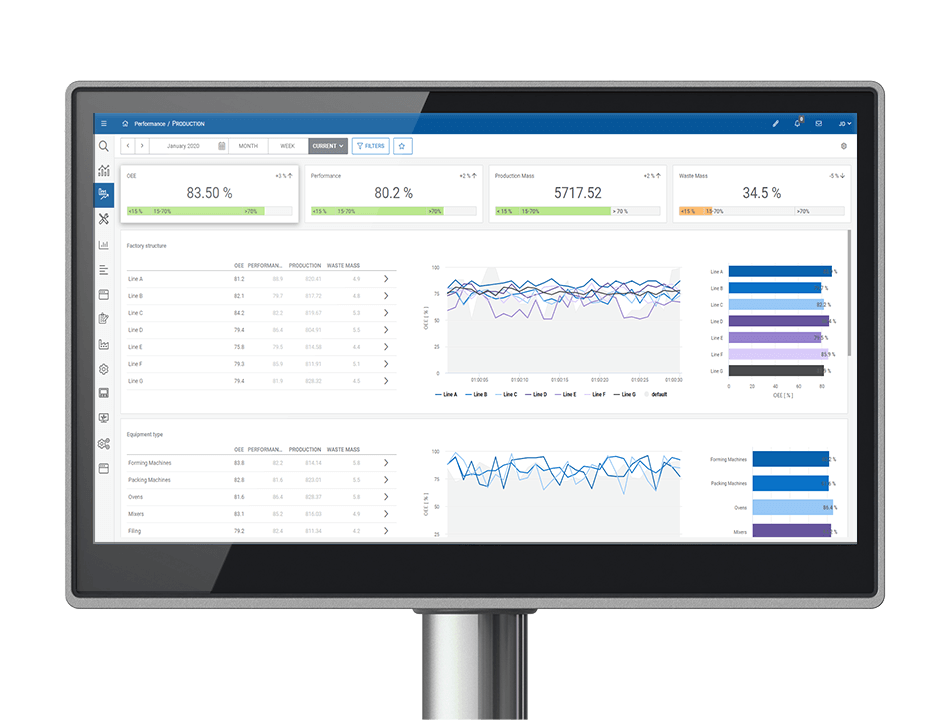

Harness the power of technology and data-driven insights to supercharge your production process. Our MES system is packed with features specifically tailored for FMCG manufacturing, each aiming to iron out inefficiencies, boost productivity, and reduce unnecessary downtimes.

Máquina

Connectivity

Seamless machine integration ensures real-time data capture and analysis.

Operator Panel with Micro Stops Monitoring

Empower operators with an intuitive interface, making downtime monitoring a breeze.

Micro Stops and

Supervisión de la OEE

Delve deep into Overall Equipment Effectiveness, focusing particularly on micro stops.

Trazabilidad

From component scanning to batch records, ensure absolute transparency and validity in every step.

Changeovers, SMEJ, Clean Inspect Lubricate

Enhanced transition procedures ensure machine readiness at all times.

Paperless Environment

Step into the future with reduced paperwork, ensuring efficiency and environmental responsibility.

Whether it’s sugar, biscuits, flour, yoghurt, or pasta – our MES system is designed to meet the diverse needs of the FMCG sector. Boost efficiency, reduce waste, and improve productivity across the board.

Invest in the future of FMCG manufacturing. Equip your enterprise with a system that truly understands and addresses the intricacies of micro stops. Reach out today and set the gears of progress in motion.

Reliable reporting, Insights into aggregated results, tactical use for shiftly/weekly prioritization per Loss Category. 100% flexibility in accounting for user’s KPI standards, good understanding of Lean Manufacturing KPIs

Tonci M., Global Manufacturing Systems Manager

Thanks to MES system we are able to tracking a present production situation information about failures and potential risks – all information might to be recalculated into KPI Table supporting a Management proces.

Verified Reviewer from Capterra., Digilal Project Leader at Food & Beverages

Accevo sp. z o.o.

Al. Pokoju 18B

31-564 Kraków, Poland

VAT ID: PL6792888061

+48 12 296 50 40

Accevo Systems (formerly ANT Solutions) provides digital solutions to manufacturing companies.

Website: Accevo Systems (antes ANT Solutions)

Al facilitar su dirección de correo electrónico y hacer clic en el botón "Descargar un catálogo", acepta recibir nuestro boletín.