Pharma Manufacturing

Improve all your production processes in your pharmaceutical facility. Implement modern pharma MES/EBR systems to ensure quality and simplify the workflows.

Streamline processes and witness up to a 15% better batch release, ensuring quicker time-to-market and superior product quality.

See tangible growth in OEE and an overall performance boost of 2.5%, thanks to automatic data collection.

By leveraging our system, drastically reduce the pitfalls and inefficiencies caused by manual errors thanks to operators panels and digital guides.

Crafted with the pharma industry’s nuances in mind, our MES system combines cutting-edge technology with sector-specific features. This synergy ensures that you not only meet the stringent regulatory requirements but also achieve unparalleled operational efficiency, every single day.

Máquina

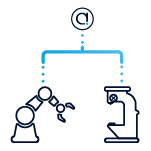

Conectividad

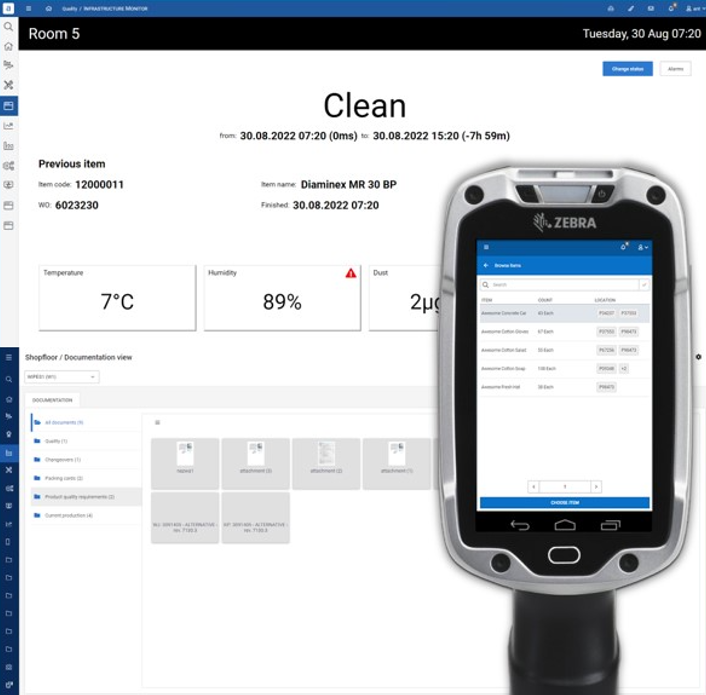

Experience seamless integration across devices, machines, and platforms, ensuring synchronized operations.

IPC and Automatic Data Validation

Benefit from In-Process Controls and a robust automated data validation mechanism that guarantees the precision of every batch.

MBR/EBR Capabilities

Transition from traditional paper-based systems to electronic batch records (EBR) and master batch records (MBR), optimizing efficiency and reducing errors.

Trazabilidad

Desde el escaneado de componentes hasta los registros de lotes, garantice una transparencia y validez absolutas en cada paso.

Operator Error Reduction

Minimize human-induced errors through guided operations, machine learning prompts, and real-time error checks.

Improve Quality

Minimize human-induced errors through guided operations, machine learning prompts, and real-time error checks.

Model solution on 3 packaging lines in 3 months

Siemens and B&R PLCs integration and hardware installation for all lines in 2 weeks

Polonia

Complete production shop floor integration

Integration with Blister Machines, Checkweighers, Serializer, Case Packer

North Macedonia

11 lines in 2 months

Siemens PLCs integration, signals duplications and hardware installation for all machines in 2 weeks

Hungary

Accevo sp. z o.o.

Al. Pokoju 18B

31-564 Cracovia, Polonia

CIF PL6792888061

+48 12 296 50 40

Accevo Systems (antes ANT Solutions) ofrece soluciones digitales a empresas manufactureras.

Página web: Accevo Systems (antes ANT Solutions)

Al facilitar su dirección de correo electrónico y hacer clic en el botón "Descargar un catálogo", acepta recibir nuestro boletín.