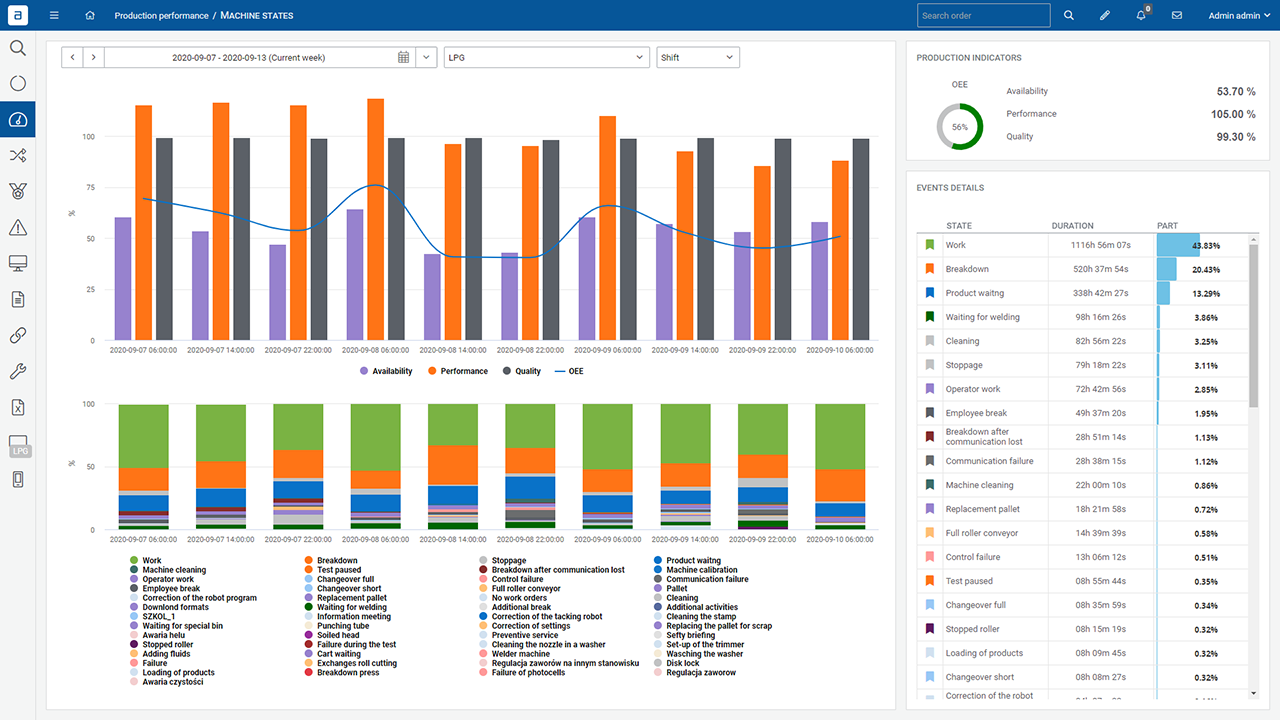

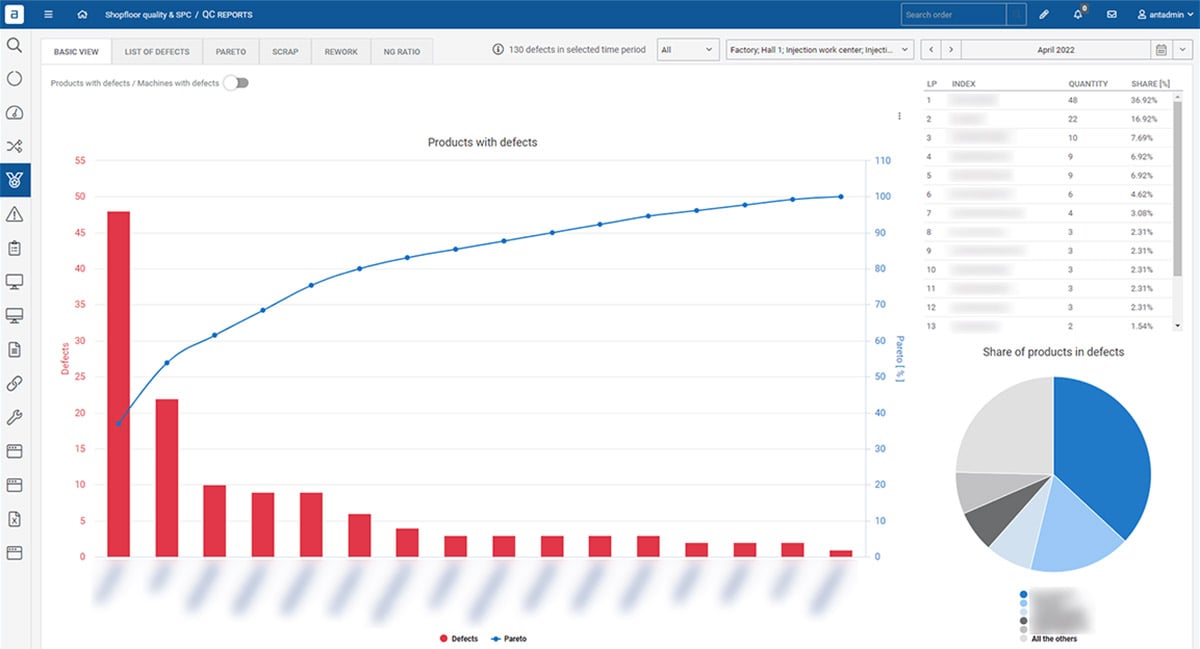

Dashboards & Reports module is a complex analytic platform with ready-to-use reports. More than dozen reports to analyze production, quality, trends and targets and get various production insights. Reports can be viewed from the perspective of plant, machine and in different time ranges.

How to analyze production process?

The daily rush makes it difficult for us to stop, create reports and production comparisons. Accevo dashboards and reports allow you to easily see your factory from different perspectives and quickly understand trends and issues. Check performance, availability and quality against specific production orders, plants divisions or machines.

How to check why you missed the production deadline?

The OEE waterfall is a powerful tool that will quickly give you the answer to the main reasons why your production plan is not being met. Check OEE drops defined according to your glossary and do a dig-down analysis to find root causes.

Main features

Various reports for production, machines, quality

Dashboard for ongoing production

Different angle for data analytics

Principales ventajas

Automatic and fast reports generation

Quick access to aggregated and detailed data

Data export to Excel for custom reports creation

What can you monitor

The system presents production reports:

• Shift, day, week, month summary: good and defected production, OEE

• Machine’s performance: good and defected production

• Realization of production target

• Number and duration of failures, breakdowns, microstops

• Calculated item’s real cycle time for operations

• Graphical presentation of realized production orders on machines

• Comparison machines for work time, stop time, OEE

• Production orders and operations report: statuses (planned orders, started orders, finished orders, delayed orders) and progress

The system presents machines data reports:

• Machines states time: work, microstops, failures, breakdowns

• % share of machine states

• % share of machine stop reason

The system presents quality reports:

• Defects Pareto for items and defect types

• Quantity of defects, scrap, and reworks for a selected time range

• Most defective machines and items

Also, the system presents trends charts with OEE, availability, performance, quality, production quantity, machine main state, number and time for changeovers and failures, MTBF/MTTF/MTTR

Artículos relacionados

¿Cómo hacer más eficaces sus reuniones en el taller?

Las reuniones en el taller son prácticamente cotidianas y esenciales para que todo funcione con eficiencia y eficacia. El tipo y la cantidad de

¿Cómo controlar eficazmente el progreso de la producción en tiempo real?

El seguimiento de los cambios en la producción -progresos, plazos de entrega, posibles fuentes de retrasos- desempeña un papel especialmente importante en la industria. Entrega de productos

¿Cómo supervisar y controlar una cadena de montaje automatizada?

Con la llegada de la Industria 4.0, la automatización ampliamente definida de las líneas de producción se ha convertido en un estándar, sin el cual es difícil imaginar una moderna