Accevo

Productos

Control del rendimiento OEE | MES | Máquina inteligente | Sin papel

Software listo para usar en su fábrica

Seleccione

Categoría

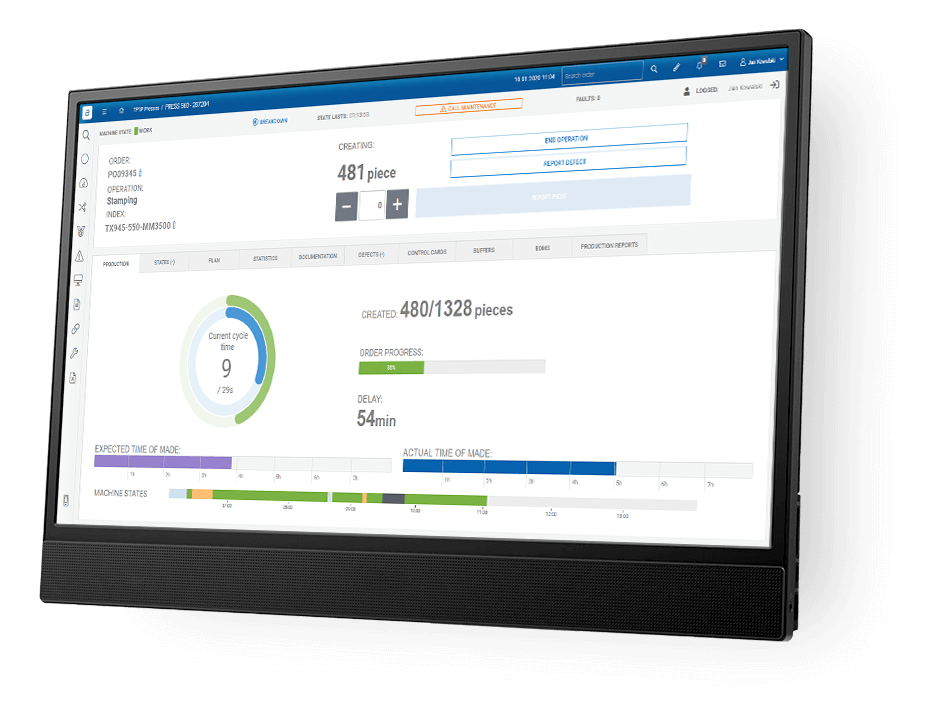

CONTROL DEL RENDIMIENTO DEL OEE

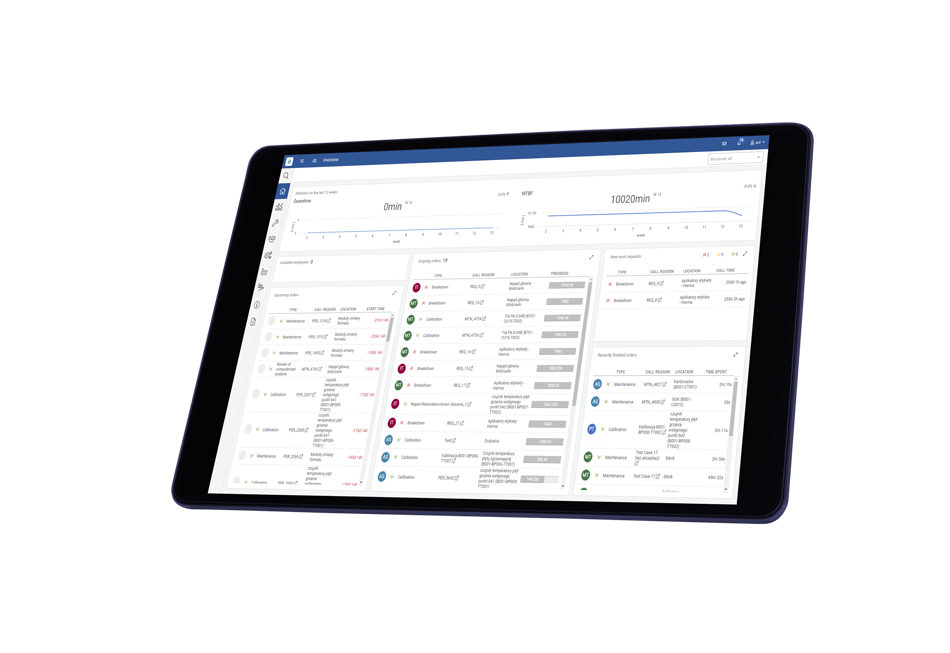

El sistema se centra en recopilar datos de las máquinas, informar sobre la producción y calcular el factor OEE en tiempo real. El sistema de supervisión del rendimiento OEE ayuda a las fábricas a dar el primer paso para supervisar la producción, su progreso y tener el proceso de fabricación bajo control.

- reducción de los tiempos de inactividad

- informes de producción más rápidos

- menor tiempo de reacción

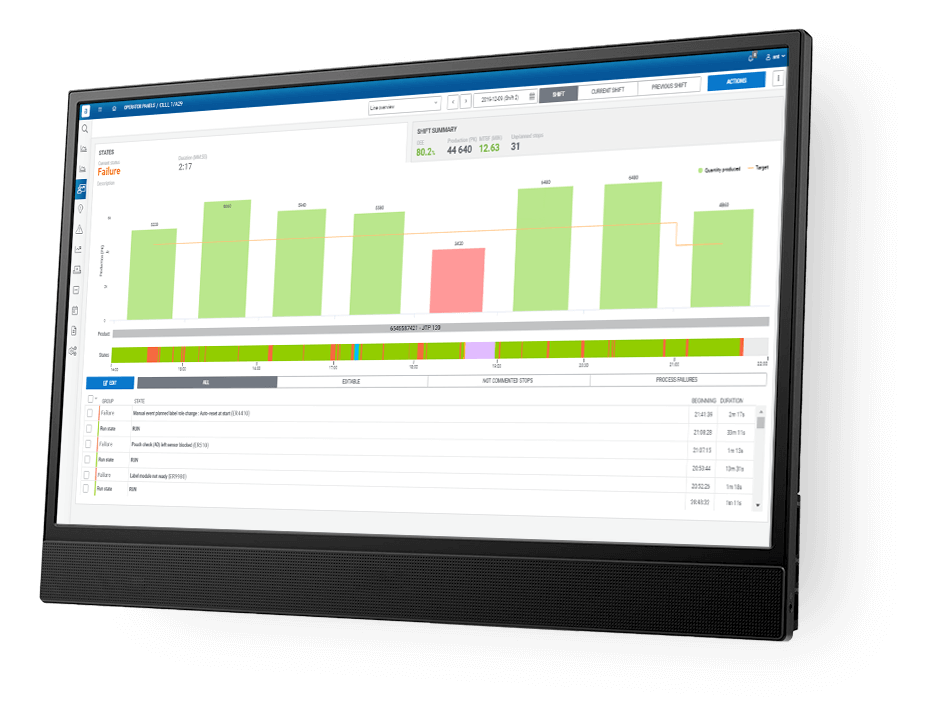

SISTEMA DE EJECUCIÓN DE FABRICACIÓN (MES)

Modern Manufacturing Execution System (MES) es un sistema integral de supervisión del rendimiento OEE con trazabilidad completa, inspecciones de calidad y gestión de reprocesamientos. Se hace hincapié en la normalización de los procesos, garantizando mediciones periódicas de la calidad, mecanismos de validación y una mayor automatización.

- consiga menos tiempos de inactividad y un mayor volumen de producción

- reducir los residuos

- validar y controlar la producción con facilidad

SISTEMA DE GESTIÓN DE OPERACIONES DE FABRICACIÓN (MOM)

Manufacturing Data Operations System (MOM) es un MES ampliado con supervisión de microparadas, control de máquinas y Paperless. Integración aún más profunda con el nivel de automatización para supervisar cada parada, enviar recetas y programas al PLC y crear formularios digitales para eliminar el papel actual en la producción.

- minimizar los tiempos de inactividad

- hacer cambios más rápidos

- mejorar la eficacia de la producción

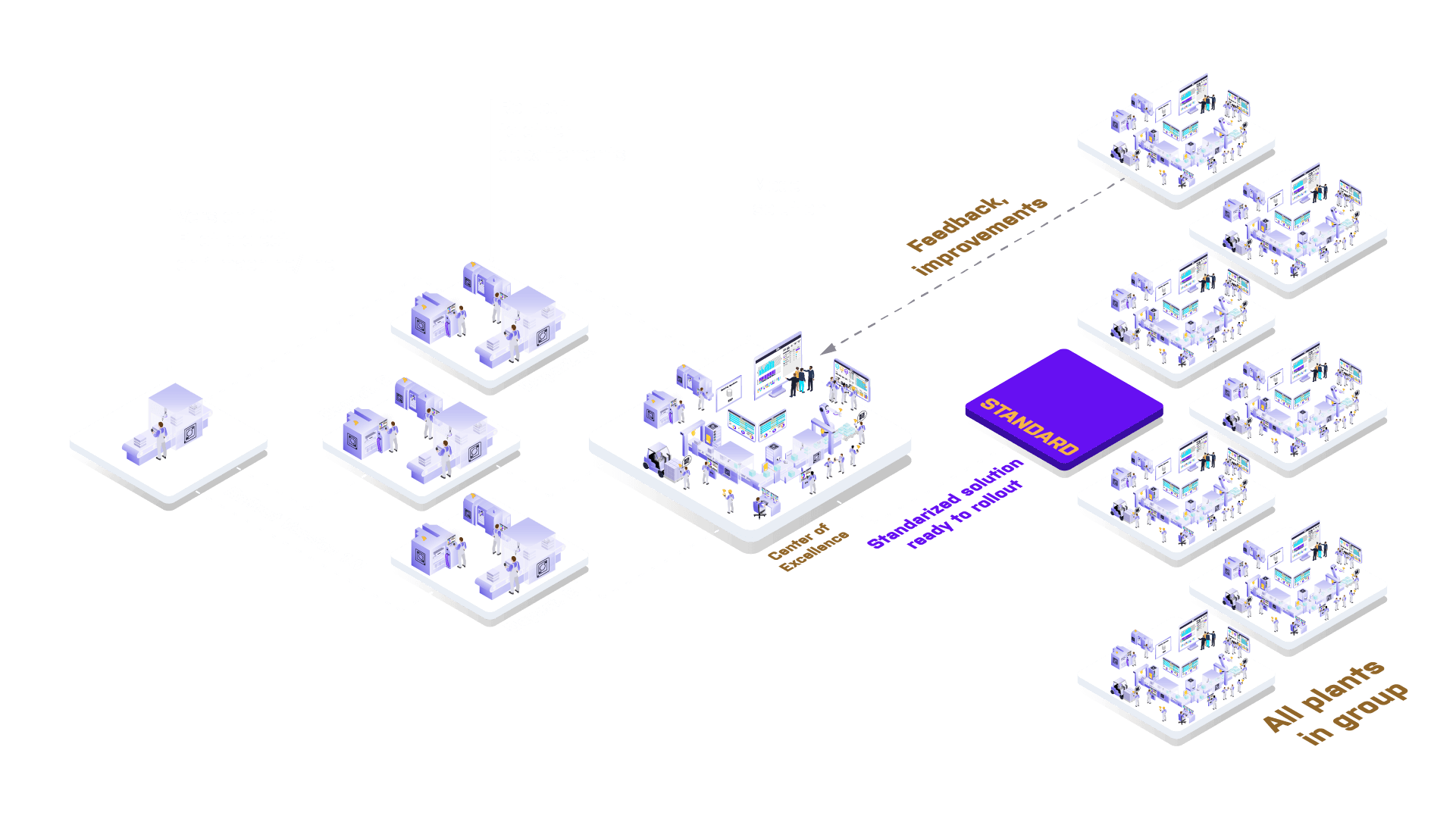

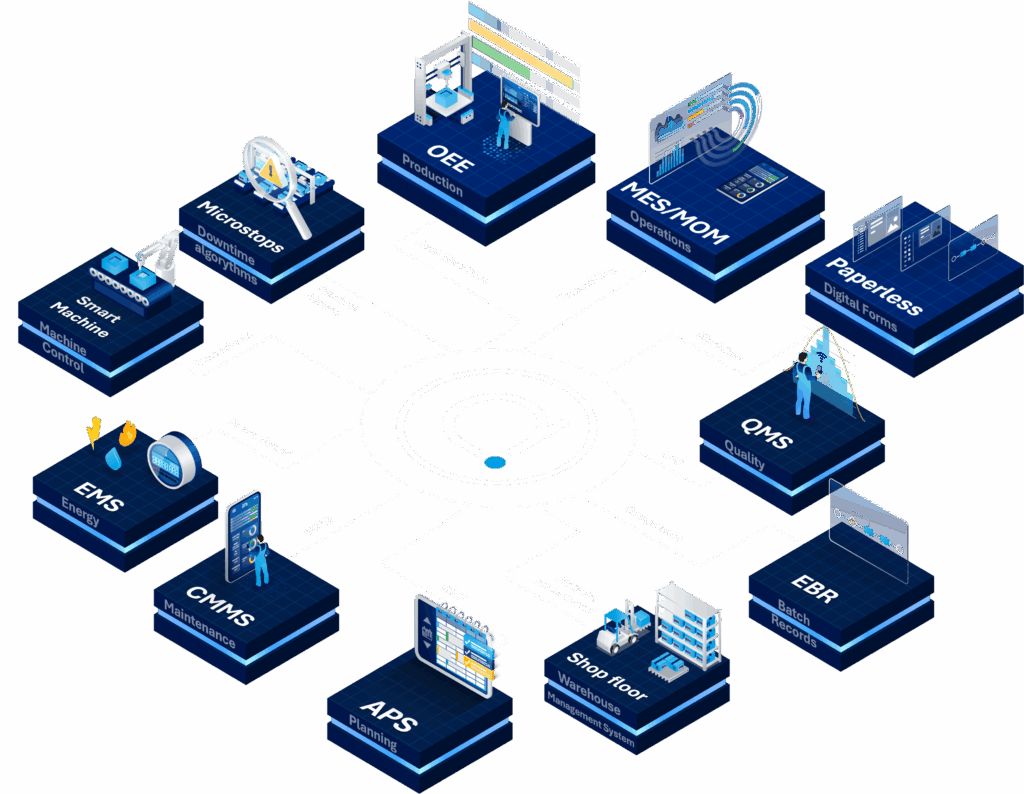

Hoja de ruta hacia la excelencia digital

Construcción modular perfectamente adaptada a su hoja de ruta de digitalización

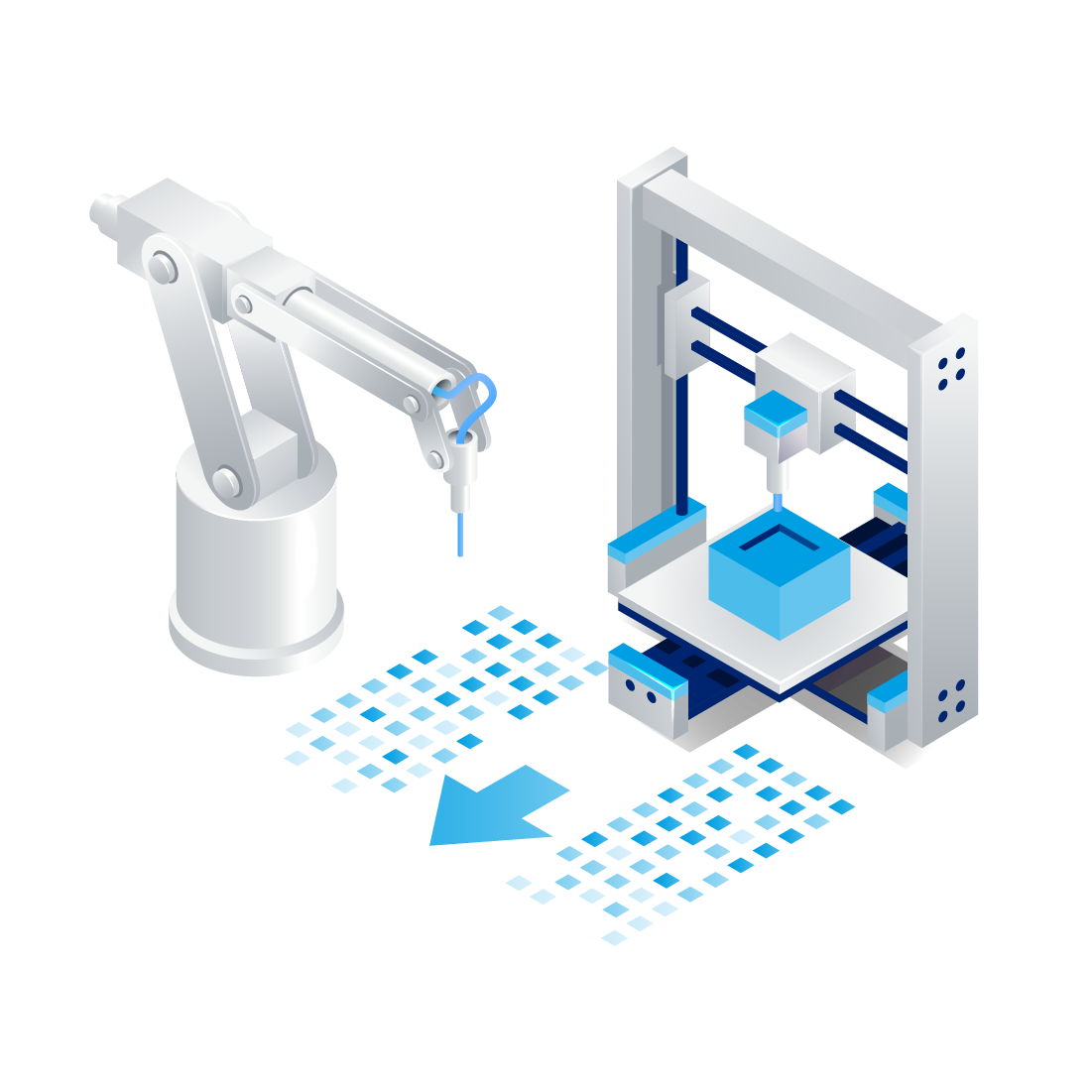

MÁQUINA INTELIGENTE (SM)

Smart Machine es un completo sistema de control de línea que soporta todas las operaciones y actividades de los operarios dedicados a las líneas de montaje automatizadas. El sistema proporciona cambios automatizados sobre la marcha y un control de línea avanzado de todos los WPC de cada estación.

- aumentar el volumen de producción

- realizar cambios más rápidos sobre la marcha

- reducir los residuos gracias al control de calidad 100%

Energía y servicios públicos

SISTEMA DE GESTIÓN DE LA ENERGÍA

El sistema de supervisión de la energía (EMS) permite controlar en tiempo real el consumo de todos los servicios utilizados en la fábrica: energía eléctrica, gas, agua, aire comprimido, calor o vapor. Ayuda a detectar gastos excesivos, pérdidas en modo de espera o consumo sin producción.

- menores gastos en servicios públicos

- reducir las pérdidas de los servicios de reserva

- detección de fugas

Suscríbase a nuestro boletín

Mejora continua

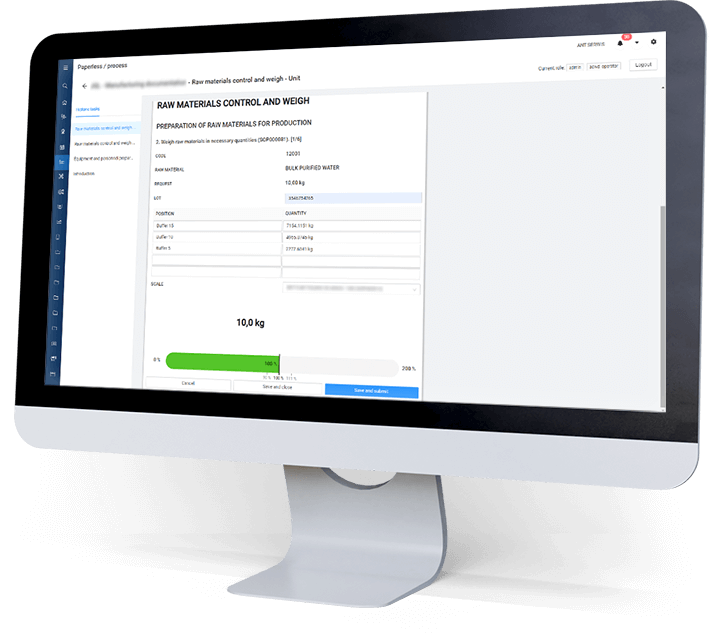

Registro electrónico de lotes (EBR)

La tecnología de registro electrónico de lotes (EBR) se utiliza para controlar el proceso de fabricación. Comprende el seguimiento de los datos de producción, la creación de informes y el control de la creación de varios lotes.

- reducir el tiempo de control de lotes

- reducir el tiempo de liberación de los lotes

- mitigar errores y desviaciones

Sistemas de calidad, planificación, mantenimiento y almacenamiento

Sistema avanzado de planificación y programación (APS)

Aumente continuamente la productividad con la ayuda de un sofisticado algoritmo. La información del ciclo en tiempo real basada en datos anteriores puede utilizarse para reprogramar automáticamente los planes e introducir planes más realistas mediante una interfaz de arrastrar y soltar.

- reducir el tiempo dedicado a actualizar manualmente el progreso del plan

- La producción en un solo turno puede garantizar la entrega a tiempo al tiempo que sustituye a la producción en dos turnos.

- cumplir los plazos de entrega a pesar de los cambios dinámicos de prioridades

Con el GMAO de Accevo, un nuevo sistema de mantenimiento que le permite programar reparaciones e inspecciones en función del tiempo de trabajo real del ciclo de la máquina, puede planificar, gestionar y responder.

- reducir las paradas y los tiempos de inactividad

- reducir el número total de reparaciones

- aumentar los indicadores clave de mantenimiento MTTF, MTBF

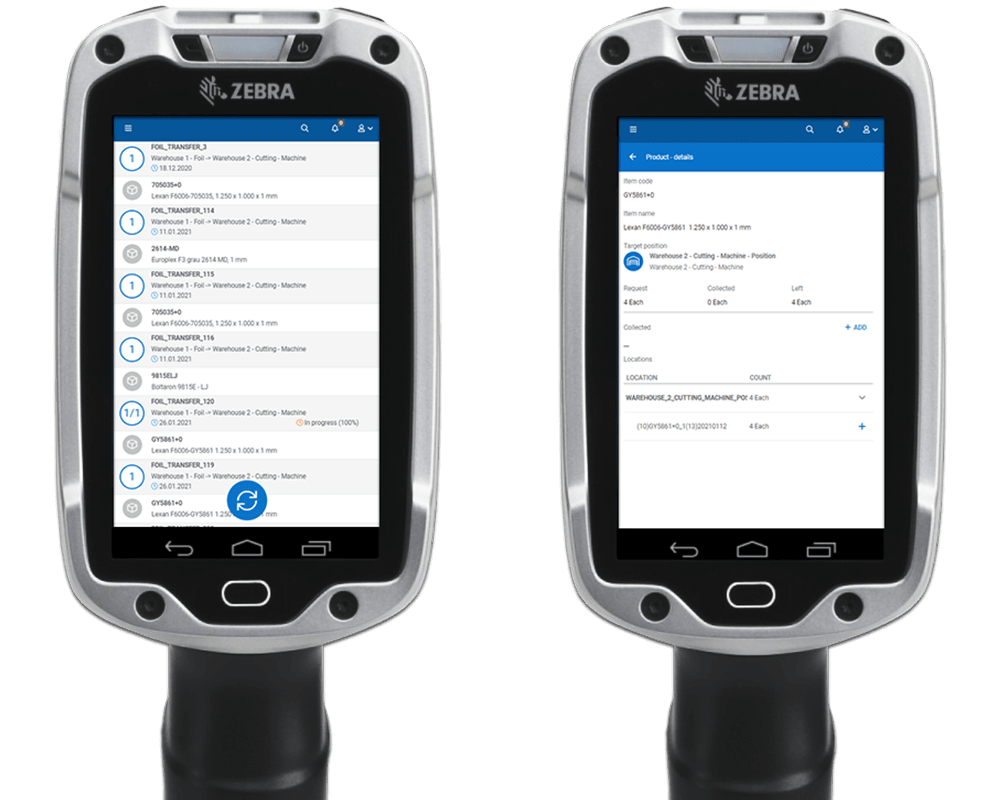

Los usuarios del sistema de gestión de almacenes (SGA) Accevo pueden gestionar los almacenes seleccionando los productos adecuados y localizándolos mediante una interfaz de usuario intuitiva y actualizaciones de existencias en tiempo real. Para acelerar el proceso de producción, envíe suministros y piezas justo a tiempo.

- encontrar y localizar suministros y productos más rápidamente

- seguimiento y localización de todas las admisiones

- analizar informes

Sistema de gestión de la calidad (SGC)

Gestión del plan de control de entrada con planificación de inspecciones, lista de comprobaciones de puesta en marcha para liberar el turno de producción y garantizar el control de calidad. Generación de informes como auditorías de productos, auditorías 5S o TPM.

- menos defectos y desechos

- tiempo ahorrado

- coste reducido

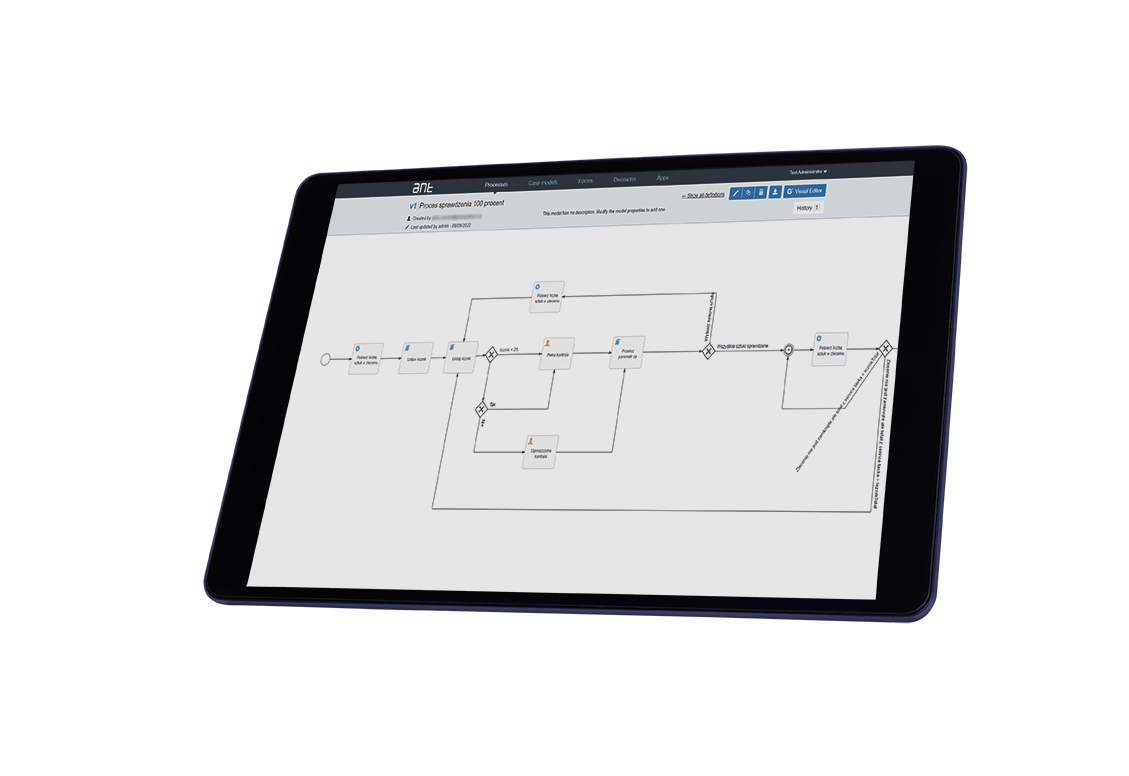

Modificaciones

Plataforma flexible y fácil de adaptar a las necesidades del cliente

Empezar poco a poco, escalar rápido