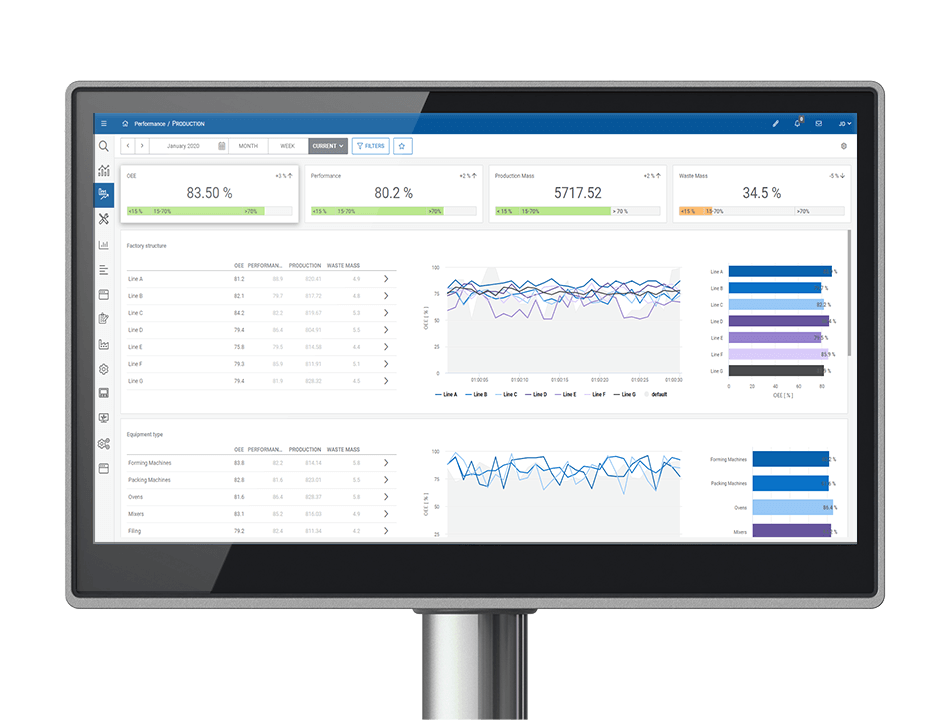

Track and improve Overall Equipment Effectiveness (OEE) with real-time performance insights. Whether you operate 10 or 100 production lines or just a few, our system provides clear visibility and actionable data to help you boost productivity.

Eliminate paper-based processes with a fully paperless environment. Manage everything from production workflows to quality and statistical process control (SPC) digitally, reducing errors and saving time.

Our MES system is hosted on Azure Cloud, ensuring your data is secure, accessible and scalable. Enjoy the benefits of high reliability and the latest in cloud technology.

Harness the power of technology and data-driven insights to supercharge your production process. Our MES system is packed with features specifically tailored for FMCG manufacturing, each aiming to iron out inefficiencies, boost productivity, and reduce unnecessary downtimes.

管理系统

连接性

Seamless machine integration ensures real-time data capture and analysis, all methods.

Operator Panel with Micro Stops Monitoring

Empower operators with an intuitive interface, making downtime monitoring a breeze.

可追溯性

From component scanning to batch records, ensure absolute transparency and validity in every step.

Integration with ERP and other external systems

Planning tools (APS), Energy Monitoring System (EMS), CMMS and more.

质量和SPC

QMS tools and statistical process control. LAB functions and skills management.

Paperless Environment

Step into the future with reduced paperwork, ensuring efficiency and environmental responsibility.

Whether it’s washing liquid, biscuits, cleaning soap, yoghurt, or pasta – our MES system is designed to meet the diverse needs of the FMCG sector. Boost efficiency, reduce waste, and improve productivity across the board.

Invest in the future of FMCG manufacturing. Equip your enterprise with a system that truly understands and addresses the intricacies of micro stops. Reach out today and set the gears of progress in motion.

可靠的报告、对汇总结果的洞察力、按损失类别进行轮班/周优先级排序的战术用途。100% 可灵活考虑用户的关键绩效指标标准,对精益生产关键绩效指标有很好的理解

Tonci M.、 全球制造系统经理

借助 MES 系统,我们能够跟踪当前的生产情况,了解故障和潜在风险的信息 - 所有信息都可以重新计算到 KPI 表中,为管理过程提供支持。

Verified Reviewer from Capterra., Digilal Project Leader at Food & Beverages

Accevo sp. z o.o.

Al. Pokoju 18B

31-564 克拉科夫,波兰

增值税编号:PL6792888061

+48 12 296 50 40

Accevo解决方案为制造业公司提供数字化解决方案。

网站: Accevo解决方案

提供您的电子邮件并点击 "下载目录 "按钮,即表示您同意接收我们的时事通讯。