Accevo Systems (formerly ANT Solutions): Your Shortcut to Smoother Production and Enhanced Performance

Accevo Systems (formerly ANT Solutions) is your reliable partner in transforming your manufacturing operations. Our customized solutions, coupled with our proven expertise and dedication, will help you achieve remarkable efficiency, optimize processes, and elevate product quality. With over 600 successful projects under our belt, we have the experience to help your business grow according to Industry40 standards.

Quadpack

Quadpack Louvrette in Kierspe and Quadpack Wood in Barcelona enhanced their cosmetics packaging production.

Kupiec

Kupiec implemented Accevo Systems (formerly ANT Solutions) to increase and optimise the production process of food, ensuring efficiency, repeatability, and compliance with procedures.

Danone

At Danone, the introduction of a complete Accevo suite, improved production efficiency and quality standards in their water bottling lines.

Asahi Breweries (formerly SAB Miller)

At Asahi Breweries in Białystok, the implementation of a solution provided by Accevo, improved tracking and efficiency in their beer production process.

Bahlsen

Bahlsen in Skawina improved their biscuits production lines by implementing Accevo FMCG System, leading to reduced rejects and enhanced production efficiency.

Carlsberg

Carlsberg’s Okocim facility in Brzesko improved their beer production efficiency and resource management.

Polish Sugar

Polish Sugar in Kruszwica improved their sugar production efficiency with the implementation of various Accevo systems.

Stock

Stock in Lublin enhanced their vodka production lines with Accevo FMCG solution, resulting in improved operational efficiency.

Imperial Tobacco

Imperial Tobacco enhanced energy, gas, water, and air management in their cigarette production process with the implementation of an Accevo system.

Pfeifer & Langen

Pfeifer & Langen enhanced their sugar production process by adopting FMCG system.

MOWI

MOWI in Ustka improved their fish production efficiency thanks to Accevo Systems (formerly ANT Solutions).

Grand Tobacco

Grand Tobacco in Yerevan enhanced their cigarette production process.

Carlsberg

Carlsberg’s Okocim facility in Brzesko improved their beer production efficiency and resource management.

Żywiec / Danone

Żywiec / Danone introduced an Accevo system improving energy management in their beer production process.

Stako / Westport Fuel Systems Group

Stako / Westport in Słupsk enhanced their LPG tank production with Accevo System for improved operational efficiency.

Nippon Seiki

Nippon-Seiki in Ksawerów enhanced their head-up display production for automotive with Accevo System improving manufacturing precision and control.

Worhtinton Industies

Worthington Industries in Słupsk enhanced their CNG tank production with for efficient labeling.

FIAT

FIAT in Bielsko-Biała enhanced their diesel engine production for improved efficiency.

MAHLE

MAHLE in Šempeter pri Gorici, Slovenia, implemented Smart Machine technology in their actuators production, enhancing process control and data management.

Adient

Adient in Skarbimierz enhanced their passenger car seat production with Accevo System.

Wielton

Wielton in Wieluń introduced a Accevo System system for their car semitrailers production.

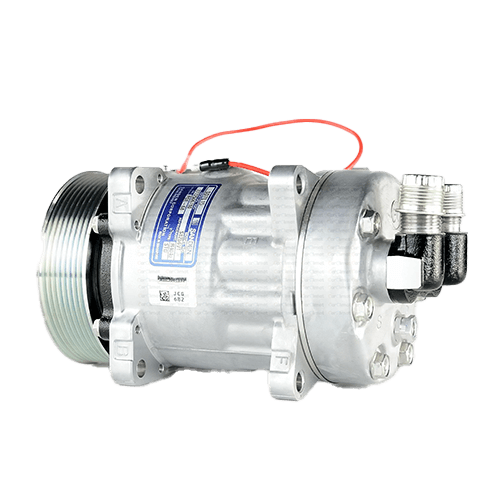

Sanden

Sanden in Polkowice improved their compressor and heater production with Accevo System.

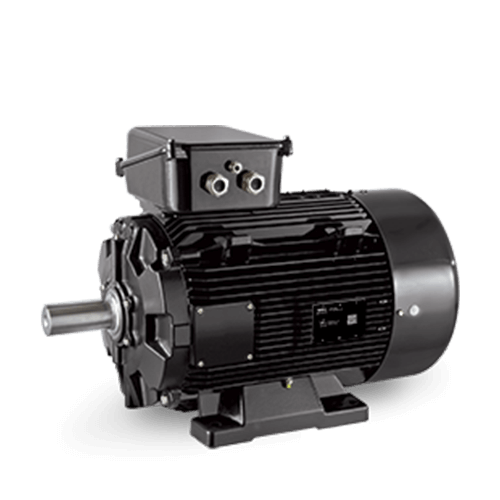

NIDEC

NIDEC in Niepołomice implemented Smart Machine technology in their engine production for enhanced production control.

RECARO / Adient

RECARO / Adient in Skarbimierz improved their truck seat production with Accevo System.

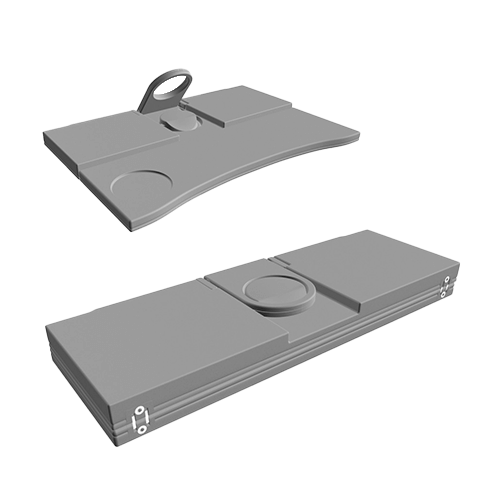

Ebco

Ebco in Albbruck, Germany, enhanced their airplane table production leading to improved manufacturing efficiency and tracking.

Prima

Prima Sosnowiec (formerly Magneti Marelli) in Sosnowiec improved their headlights and fuel tanks production.

AGC Automotive Poland

AGC formerly NordGlass improved their glass and windscreens manufacturing processes.

ESAB

ESAB optimised their welding wire production thanks to a complete Accevo system implementation.

Servier

Servier improved their tablets in blisters or bottles production with Accevo system promoting operational efficiency.

Gedeon Richter

Gedeon Richter in Grodzisk Mazowiecki focused on enhancing their blister lines streamlining production processes.

Alkaloid AD Skopje

Alkaloid in Skopje improved their pills and liquids production integrating various devices and technologies for enhanced production efficiency.

Novartis / Sandoz

Novartis / Sandoz in all facilities implemented Accevo System in their tablets in blisters production for enhanced production efficiency and documentation workflow.

Servier / Anpharm

Servier / Anpharm in Warsaw introduced Accevo Systems (formerly ANT Solutions) for producing tablets in blisters, focusing on improving diagnostics and machine efficiency.

Polpharma / Polfa Warsaw

Polpharma / Polfa Warsaw in Karolkowa upgraded their eye and ear drops and ampoules production with Accevo system for improved efficiency.

Dr Irena Eris

Dr Irena Eris in Piaseczno implemented system for their diverse cosmetics production lines, ensuring efficient operation with advanced machine connectivity.

Polpharma / Medana

Polpharma / Medana in Sieradz introduced Accevo System for their eye drops production line for enhanced production efficiency.

Bormioli Pharma

Bormioli Pharma in Rivanazzano implemented Accevo system across their machines, leading to improved efficiency in pharma packaging production.

Polpharma

Polpharma in Starogard Gdański upgraded their production processes enhancing operational efficiency and data connectivity.

CETES Cosmetics (Oriflame)

CETES Cosmetics in Warszawa enhanced their cosmetics production efficiency integrating multiple interfaces and technologies.

Whirpool

Whirlpool improved their appliance production with Accevo system, monitoring various utilities, ensuring better energy and resource management.

Orzesze (CP Glass)

CP Glass in Orzesze improved their glass bottle production efficiency and resource management with the implementation of an Accevo system.

Husqvarna

Husqvarna enhanced their riders/mowers production with Accevo system streamlining their manufacturing process.

DeLaval

DeLaval improved their brush cases production with Accevo system, their own sensors on presses leading to more efficient manufacturing.

Legrand

Legrand optimised their sockets, contacts, and switches production with Accevo system.

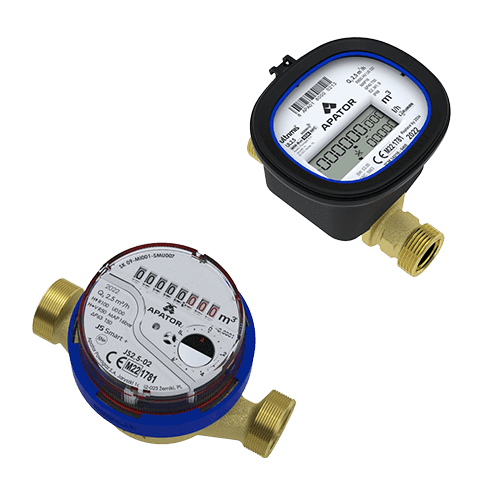

Apator

Apator implemented Accevo System in their energy meter production, focusing on improving manufacturing efficiency and precision.

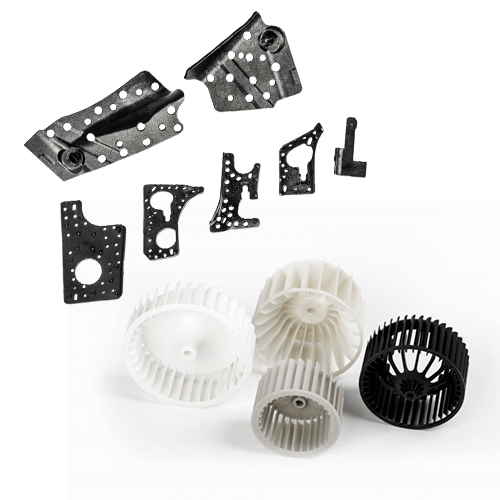

Bilplast

Bilplast enhanced their production of parts for AGD and Automotive with Accevo system, leading to more streamlined and efficient manufacturing processes.

Marelli Bielsko Biała

Marelli (formerly Magneti Marelli) in Bielsko-Biała upgraded their shock absorber production with Accevo system for improved operations.

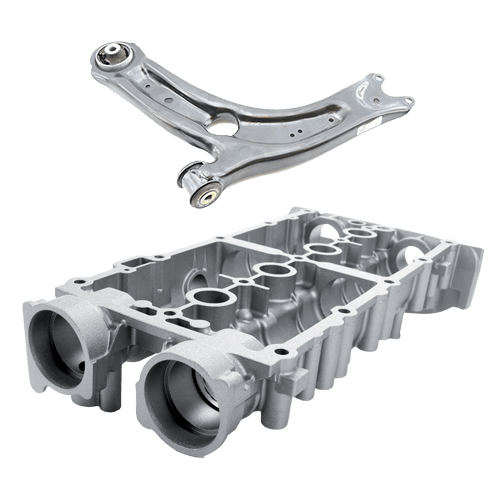

MAGNA

MAGNA updated their aluminum suspension casting production with Accevo system for better process control.

AMCOR

Amcor Poland, adopted Accevo system for their packaging and foils production, efficiently managing air and energy.

Biscuits Factory

- Find out what problems biccuits factory was facing before implementation OEE factory software.

- What was Accevo Systems (formerly ANT Solutions) approach to deal with uncovered factory issues.

- How Accevo Systems (formerly ANT Solutions) implemented the key software components including hardware and cabling.

- The final outcome resulted in key KPIs increase.

Assembly Factory

- Company implemented an MES system to improve manufacturing efficiency.

- The MES system enabled real-time production monitoring, quality inspections, and defect handling.

- The MES system helped factory to increase efficiency, reduce defective products, and improve data accuracy.

- Find out how Accevo Systems (formerly ANT Solutions) MES implementation, helped manufacturer increasing it’s KPIs.

Tabacco Plant

- This case study describes the customer case study of a successful micro stops implementation in a tobacco factory.

- The factory system enabled automated data gathering and key algorithmics.

- The system was implemented to address the challenges of high-speed production, micro stops, SKU and changeover times, and a diverse machine park.

- Find out how Accevo Systems (formerly ANT Solutions) enabled communication with over 100 machine types, algorithmics creation, and roll-out to 30 factories.