Accevo: About Us

Welcome to Accevo. Welcome to the future of manufacturing.

For nearly two decades, Accevo (formerly ANT Solutions) has been at the forefront of digital manufacturing transformation, helping global leaders achieve operational excellence, agility, and innovation.

With 19 years of experience, more than 850 successful projects across 38 countries, and a team of 160 software engineers, we empower manufacturers to harness the full potential of Industry 4.0 and Smart Factory technologies.

As part of the Dürr Group and the iTAC Network, we combine global reach with local expertise to deliver scalable, future-ready solutions that seamlessly connect machines, systems, and people.

Our Mission

Accevo: Accelerating Manufacturing Evolution

Our mission is to empower manufacturers to optimize production, eliminate inefficiencies, and embrace data-driven decision-making.

Through innovation, adaptability, and deep industry expertise, we help factories transform into fully connected, intelligent, and predictive ecosystems.

=

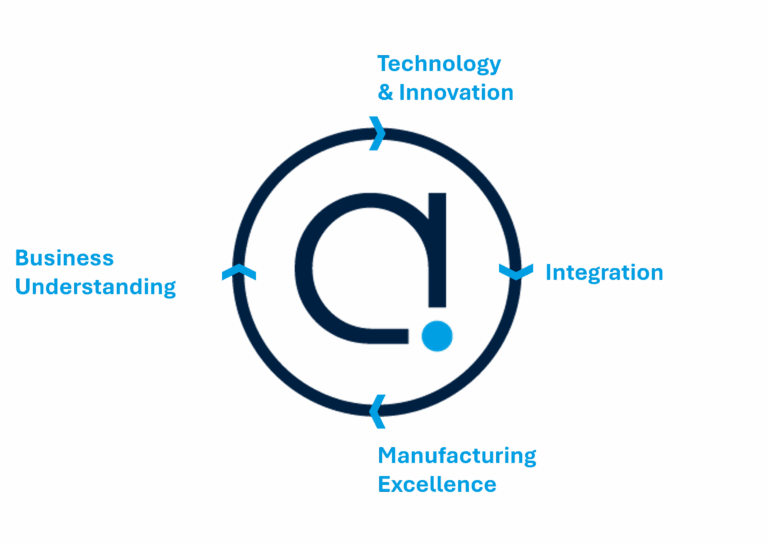

Our Four Strategic Pillars

Proven Framework For Digitalization Success

Business Understanding

We don’t just deliver software — we understand your business.

- 19 years of expertise in digital manufacturing

- Business and technical consulting to align IT and operations

- On-site analysis to identify pain points and optimize processes

- Strategic advisory based on hundreds of global implementations

Technology & Innovation

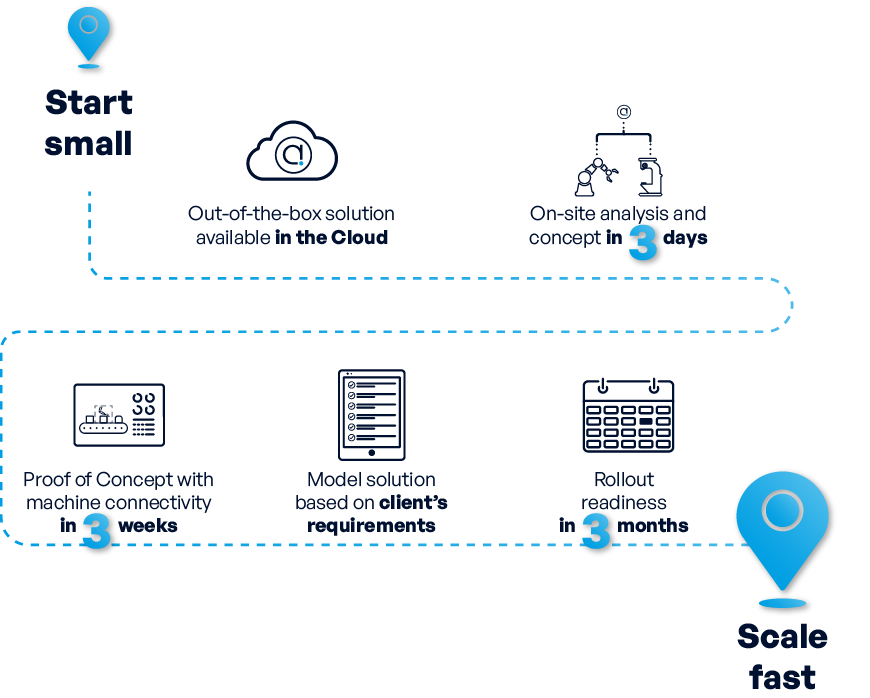

We design solutions that are scalable, future-ready, and fast to deploy.

- cloud-native or on-premise deployments

- Modern microservices architecture for maximum flexibility

- Out-of-the-box software combined with our 80/20 strategy:

80% ready-to-use, 20% tailored to your needs - Rapid implementation with minimal disruption

- Continuous innovation powered by AI, IoT and predictive analytics

Manufacturing Excellence

We help manufacturers achieve measurable business value.

- Proven know-how from 850+ successful projects

- Real-time data analytics for better visibility and faster decisions

- Predictive insights powered by machine learning

- Benefit Tracker to monitor ROI across initiatives

- Achieving fast, measurable returns on digital transformation

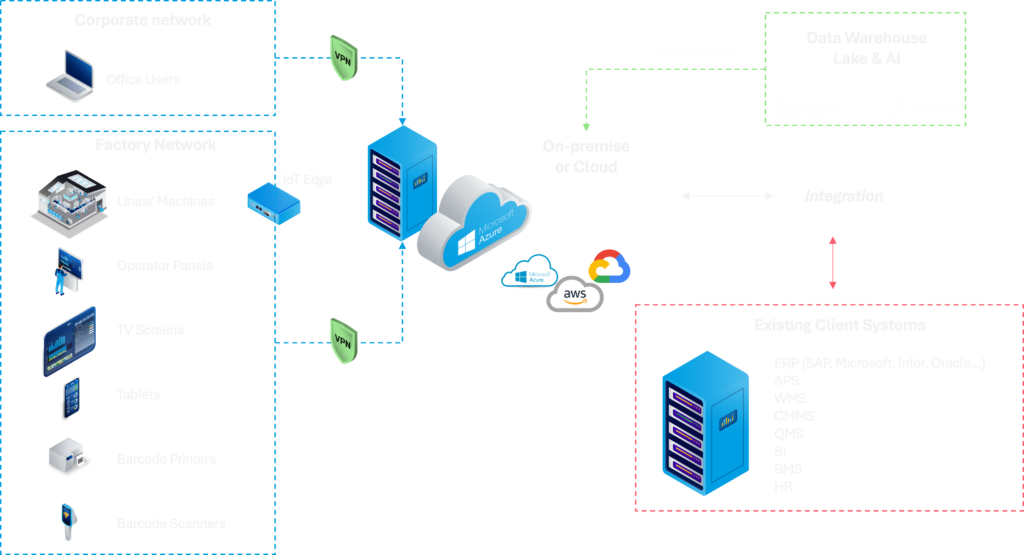

Integration

We make your entire factory connected and intelligent.

- IoT-driven machine connectivity for real-time data insights

- ERP and external system integration

- Hardware installation and integration services

- Centralized data warehouses, BI dashboards, and AI analytics

- Standardized global rollouts with local adaptation

Trusted by Global Leaders

We partner with some of the most advanced and innovative manufacturing companies worldwide, supporting their journey towards digital transformation, operational excellence, and Industry 4.0 leadership.

Our solutions power global leaders pharma, FMCG, automotive, and industrial manufacturing.

Accevo works hand in hand with the world’s top manufacturers, helping them unlock new levels of performance, efficiency, and innovation. Through deep business understanding, proven methodologies, and cutting-edge technology, we deliver tangible, measurable results.

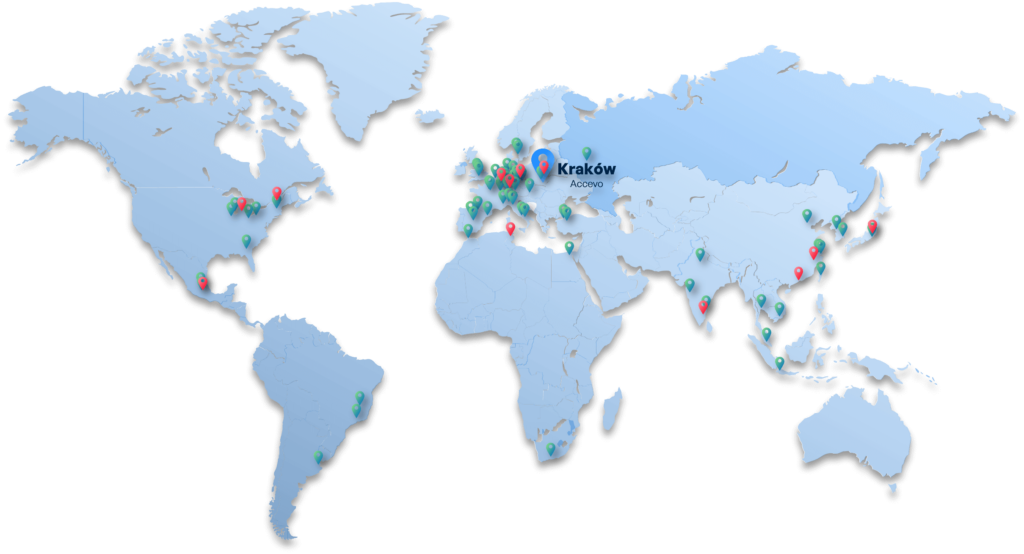

Global Footprint – Powered by ITAC Network

As part of the Dürr Digital Factory ecosystem and the iTAC Network, we leverage global expertise to deliver large-scale, multi-site MES and MOM rollouts.

Through collaboration with iTAC, Cogiscan, and Dualis, we offer an end-to-end digital manufacturing ecosystem, integrating shop-floor automation, IoT connectivity, and enterprise-level analytics.

iTAC Software AG, an independent company of the mechanical and plant engineering group Dürr, provides Internet-enabled information and communication technologies for the manufacturing industry. Founded in 1998, the company is one of the leading MES/MOM providers in Germany. The iTAC.MOM.Suite is a holistic Manufacturing Operations Management that is used worldwide by companies in different industry sectors such as automotive, electronics/EMS, telecommunication, medical engineering, metal casting and energy. Additional services and solutions for implementing IIoT and Industry 4.0 requirements complete the portfolio. iTAC Software AG is headquartered in Montabaur, Germany and has offices in the USA, Mexico, China and Japan and has a worldwide partner network for sales and service.

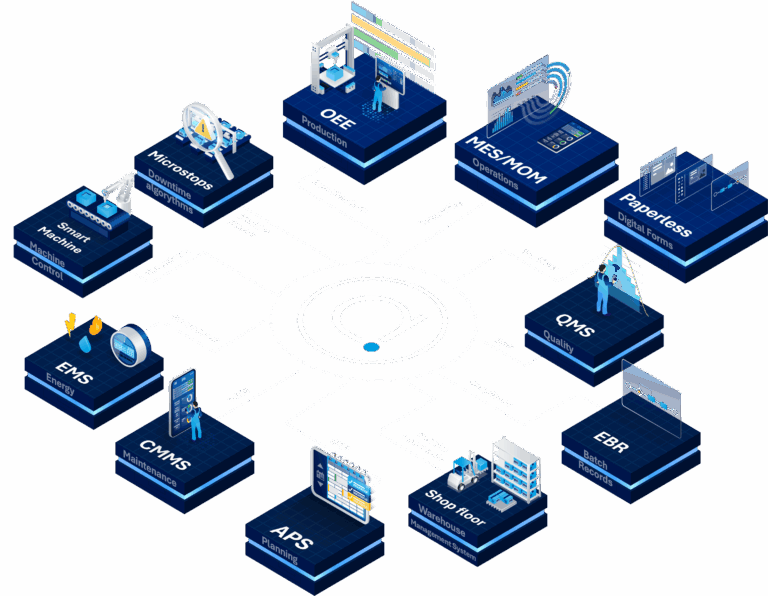

Since its foundation, Accevo has been a trusted partner in the digital transformation of manufacturing. As part of the Dürr Group, we provide an integrated Smart Factory ecosystem that connects shop floor automation with business systems to deliver real-time visibility, control, and optimisation. Our portfolio spans advanced MES and MOM platforms, predictive analytics, energy and quality management, warehouse control, and paperless production tools. Each module is designed to work seamlessly together and integrate with ERP, automation, and IIoT environments. This interconnected approach enables manufacturers across industries to boost efficiency, improve decision-making, and unlock sustainable growth.

Since 1990, DUALIS GmbH IT Solution has been your partner for agile and efficient production. As part of the iTAC Software AG and the DURR Group, we deliver a full suite of software solutions and consulting services designed to optimize your manufacturing processes. From production planning and scheduling with GANTTPLAN to intelligent space optimization with AREAPLAN and immersive 3D factory simulation with Visual Components, our tools are engineered to seamlessly integrate with each other and with external systems like ERP and MES. This synergy empowers businesses across various industries to achieve peak performance.

Cogiscan provides comprehensive and modular factory digitalization solutions tailor-made for electronics manufacturers. The applications enable machine connectivity, process control and traceability, as well as intelligent factory analytics – covering all types of manufacturing ecosystems with a vendor-agnostic approach. With installations around the globe, Cogiscan’s solutions have helped to transform and optimize manufacturing operations in over 450 factories.

Driving Innovation Through AI & R&D

At Accevo, innovation is at the core of everything we do.

We continuously invest in R&D to deliver next-generation Smart Factory solutions and shape the future of manufacturing.

AI-Powered Manufacturing Intelligence

- Predictive maintenance powered by machine learning

- AI-driven production optimization to minimize downtime and waste

- Automated anomaly detection to ensure consistent quality

- Generative AI in manufacturing intelligence — enabling real-time recommendations and data-driven decision-making

R&D for the Factories of the Future

Dedicated R&D teams co-developing innovative solutions with partners across the iTAC Network

- Investment in advanced analytics, IoT integration, and machine connectivity

- Research initiatives focused on digital twins, simulation-driven planning, and energy efficiency

- Participation in global Industry 4.0 innovation programs within the Dürr Digital Factory ecosystem

Our vision is to make manufacturing more predictive, more autonomous, and more efficient — powered by data, AI, and continuous innovation.”

Szymon Piróg | Accevo CEO

Data Security & Compliance by Design

Accevo Smart Factory solutions are compliance-ready by design, embedding security and traceability into every layer of the platform.

Key Compliance Capabilities:

- Regulatory Compliance Built-in

Native support for ISO, GMP, FDA, NIS2, CRA, and other global standards - Full Traceability

End-to-end tracking of batches, materials, and workflows across production - Audit Trail

Complete historical logs ensuring transparency and accountability - Cybersecurity by Design

Robust data privacy, encryption, and security frameworks aligned with industry best practices

By embedding compliance and security directly into the Accevo Smart Factory platform, we ensure that your factory is audit-ready and prepared for the latest global regulatory requirements — without slowing down your operations.

- Regulatory Compliance Built-in

ANT is changing!

is now

We are changing! ANT is renaming and adapting for the new era at Durr Group. The name Accevo is a blend of “Accelerate” and “Evolution,” representing our commitment to fast-tracking improvements and advancing manufacturing software in factories. Accevo means software that speeds up the evolution of production and encapsulates our core values:

- Accelerating Change: We aim to speed up the change in factories by implementing cutting-edge industrial software solutions.

- Driving Evolution: We support manufacturers in continuously improving their strategies by delivering new technologies to production facilities.

- Excellence in Software: Our focus remains on delivering software with modern architecture based on microservices and cloud environments in every project.

Our History

Accevo Systems (formerly ANT Solutions) is established, focusing on EMS products for factories.

The first global project with the Accevo MES system is launched

Accevo Systems (formerly ANT Solutions) is acquired by BBS Automation.

The first project is implemented in the cloud.

Introduction of microservices architecture for enhanced scalability and flexibility.

Accevo Systems (formerly ANT Solutions) is acquired by the Dürr Group.

Launch of the MoM paperless system, streamlining processes and reducing paperwork.

142

locations in 32 countries

20k+

employees

€4.3 mld

revenue in 2023

Sustainability at Dürr

It is part of our corporate culture at Dürr to act ethically in our day-to-day business life and to comply with prevailing laws. Rules of conduct have been defined in individual Group procedures and manuals for years. We have now concentrated these corporate principles and grouped them by theme in the Code of Conduct of the Dürr Group.

In addition, you can view the rules of behaviour applicable to our suppliers as contained in the Code of Conduct of the Dürr Group.

Further reading: Sustainability at Dürr Group.

Our sustainability concept

We take a holistic approach to sustainability.

Five fields of action form the orientation of

sustainability management in the Dürr Group:

- Products and Services

- Value Creation and Supply Chain

- Employees and Qualification

- Management and Governance

- Engagement and Society

The holistic approach of our sustainability activities and the five fields of action are reflected as segments of a leaf in our “Dürr Group Sustainability” logo.

Corporate Compliance at Dürr

Compliance means compliance with all rules which are applicable within the Dürr Group such as laws, norms, internal organizational instructions etc.

Ultimately, Compliance enables ethically correct behavior of all Dürr employees.

In addition to the contact details listed below, information to the Compliance Office can also be provided via our reporting system Dürr Group Integrity Line.

The Dürr Group Integrity Line as a component of an effective Compliance Management System is used for early detection of undesirable developments that could lead to significant risks for Dürr.

With the → Dürr Group Integrity Line, we offer the possibility of reporting compliance violations anonymously and securely or by voluntarily providing your name and data.

Code of Conduct

This Code of Conduct provides guidance for your actions. In a globalized, highly complex

working world, this Code of Conduct is designed to help you identify legal risks and avoid

legal violations. It clarifies our corporate principles and our clear commitment to compli-

ance with legal requirements and ethical standards, among others in the areas of human

rights, labor standards, corruption prevention and environmental protection. The princi-

ples listed are clearly explained to you by examples from everyday business life.

System Architecture We choose

Accevo is a Cloud Native solution built on modern technologies and a microservices architecture. This approach allows for phased implementation and the development of a tailored growth roadmap, adapting to the real needs of your company.

In addition, Accevo offers a comprehensive suite of systems, including OEE, Microstops monitoring, MoM, Paperless, EBR, CMMS, APS, and EMS.

Technologies We Use

Our technology stack is carefully selected to support a scalable, secure, and high-performance platform, enabling us to deliver exceptional experiences to our users while continuously evolving to meet future challenges.

To build and maintain our cutting-edge platform, we leverage a diverse set of modern technologies:

-

Frontend & Backend Development: We utilize TypeScript and React for creating dynamic and responsive user interfaces, while our backend is powered by Node.js and Java SpringBoot 3, ensuring robust and scalable server-side applications.

-

Data Management: Our system incorporates a timeseries database with Historian capabilities, enabling efficient storage and analysis of time-dependent data. Additionally, we utilize a data warehouse integrated with AI technologies to drive intelligent insights and decision-making.

-

Containerization & Orchestration: We deploy our services using Docker containers managed by Kubernetes, ensuring seamless scaling and orchestration across our infrastructure.

-

DevOps & Continuous Integration/Continuous Deployment (CI/CD): Our development workflow is streamlined with GitHub, CI/CD pipelines, and GitOps practices, promoting rapid and reliable software delivery.

-

Security & Authentication: We implement SAML Single Sign-On (SSO) to provide secure and streamlined authentication for our users.

-

Infrastructure Management: Embracing Infrastructure-as-Code, we use Terraform to automate and manage our cloud resources across Azure and AWS, ensuring consistency and efficiency in our deployments.

React

NodeJS

Docker

GitHub

DevOps

AWS

SSO

Java

How We Work

We provide end-to-end project delivery with a complete range of services to ensure seamless MES implementation:

- On-Site Analysis – We start with an in-depth analysis at your site, understanding unique operational needs to tailor the MES solution effectively.

- Machine Connectivity – Our expertise in automation enables us to connect every machine, regardless of complexity, ensuring full data integration across the factory floor.

- System Integration – Seamlessly integrate with your ERP systems and other business systems to enable a smooth flow of information across departments.

- Hardware Delivery – We manage the delivery and installation of all required hardware, supporting a reliable infrastructure from day one.

- System Implementation – Our skilled team implements the Accevo solutions, customizing it to meet specific manufacturing requirements and workflows.

- Training Programs – We provide comprehensive training to ensure your team maximizes the value of the new system.

- System Handover & SLA – After implementation, we conduct a formal handover and offer a service-level agreement (SLA) to ensure ongoing support and system optimization.

With Accevo Systems (formerly ANT Solutions), you gain a partner committed to delivering a fully integrated, efficient, and future-proof manufacturing environment.

Get To Know Our Solutions

Learn From Case Studies

Biscuits Factory

- Find out what problems biccuits factory was facing before implementation OEE factory software.

- What was Accevo Systems (formerly ANT Solutions) approach to deal with uncovered factory issues.

- How Accevo Systems (formerly ANT Solutions) implemented the key software components including hardware and cabling.

- The final outcome resulted in key KPIs increase.

Assembly Factory

- Company implemented an MES system to improve manufacturing efficiency.

- The MES system enabled real-time production monitoring, quality inspections, and defect handling.

- The MES system helped factory to increase efficiency, reduce defective products, and improve data accuracy.

- Find out how Accevo Systems (formerly ANT Solutions) MES implementation, helped manufacturer increasing it’s KPIs.

Tobacco Plant

- This case study describes the customer case study of a successful micro stops implementation in a tobacco factory.

- The factory system enabled automated data gathering and key algorithmics.

- The system was implemented to address the challenges of high-speed production, micro stops, SKU and changeover times, and a diverse machine park.

- Find out how Accevo Systems (formerly ANT Solutions) enabled communication with over 100 machine types, algorithmics creation, and roll-out to 30 factories.