The only one reason why to invest in MES system for your production

As the world becomes more connected and businesses strive to become more efficient, the need for advanced manufacturing technology is becoming increasingly important. One of

Limit the implementation time thanks to our Industry Suites:

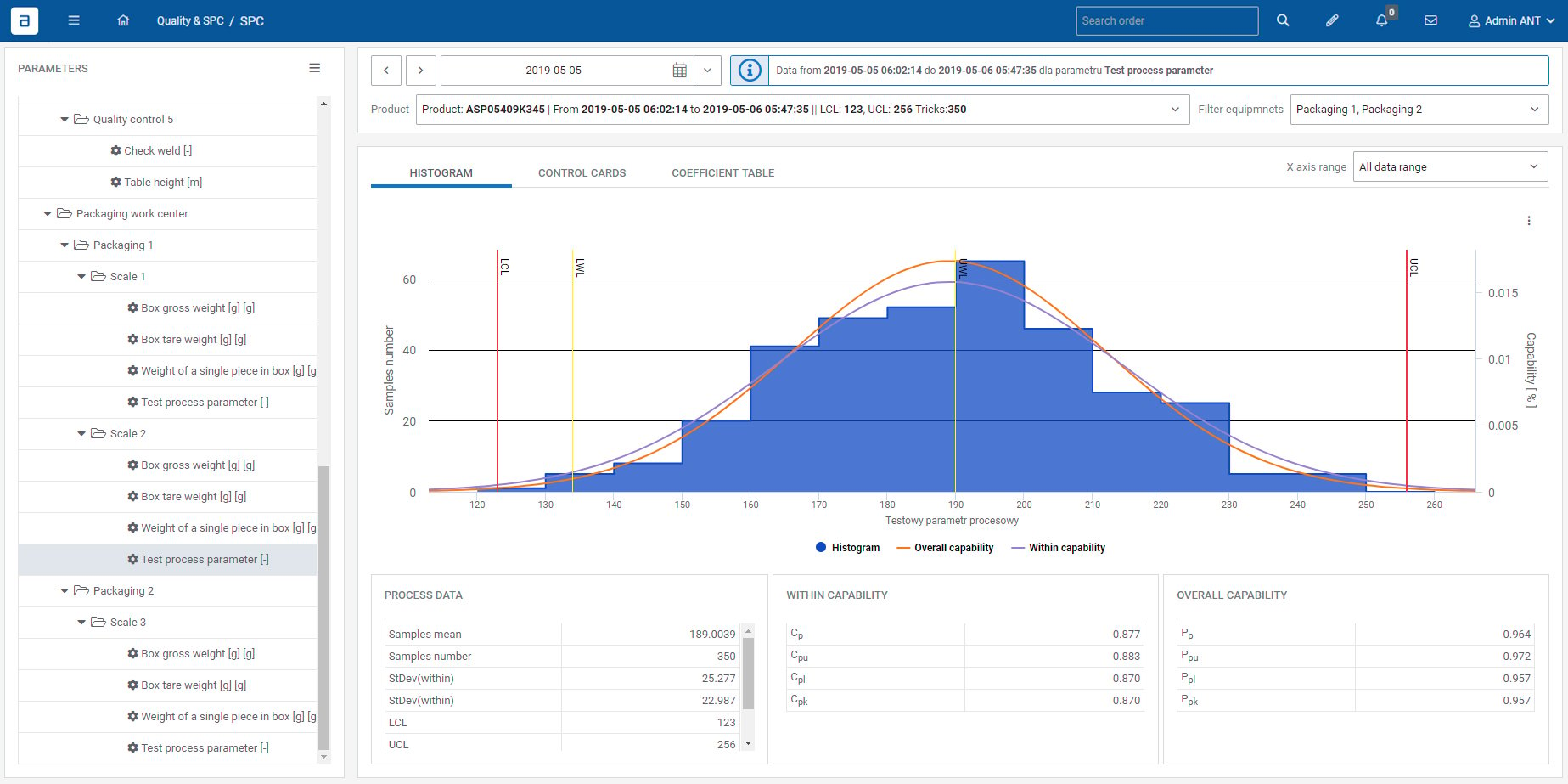

FMCG companies face frequent stoppages on the lines without the possibility to identify the root causes and bottlenecks. Needs for reduction direct production costs force factories to reduce material waste, reject and defects. We help them optimize both.

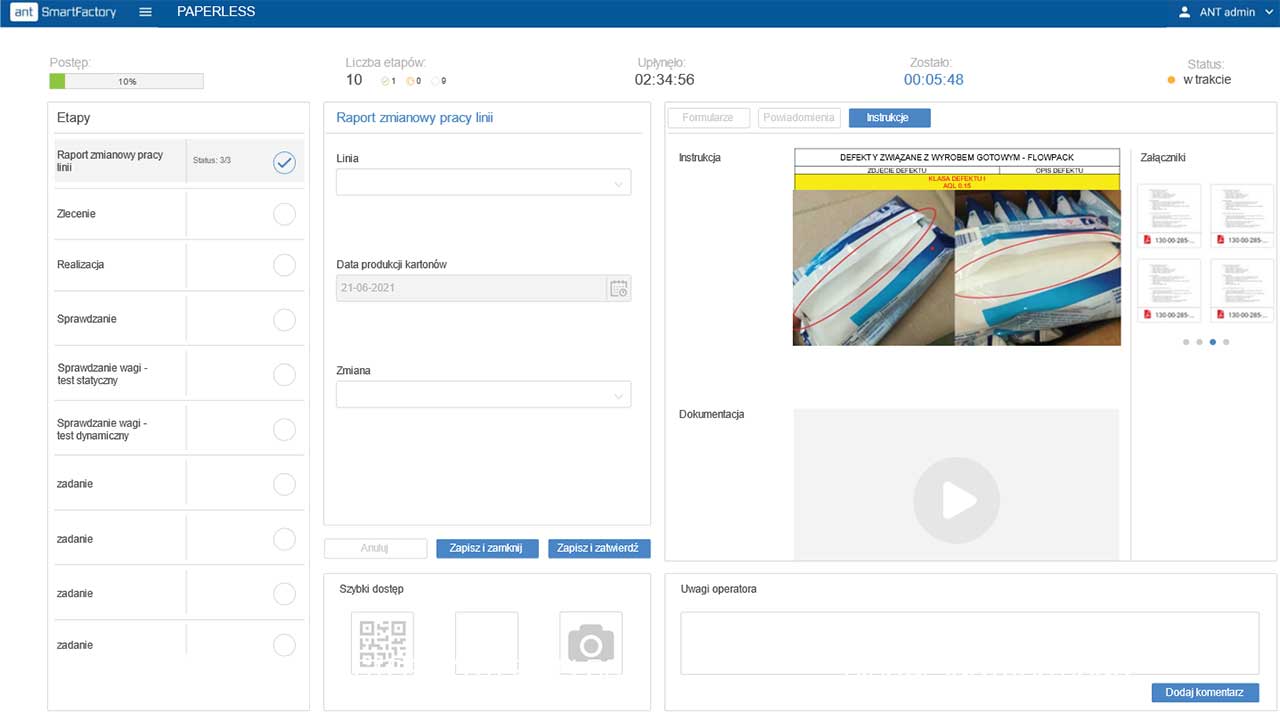

Pharma companies are looking for a reduction of the administrative time of Operators and ensure process compliance with GMP and GAMP. Factories miss automated data collection, online process control and operator guidance through the production steps based on workflow.

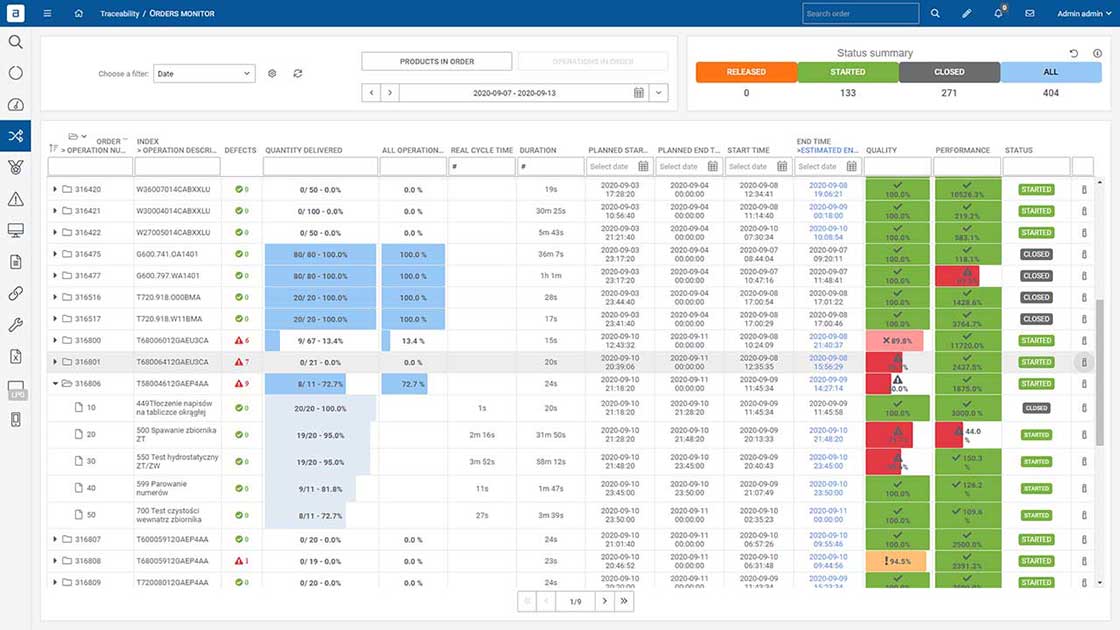

Automotive companies struggle with low availability and production performance. Market regulations require track&trace of used raw materials, components and tools together with their validation during the production.

Manufacturing companies require to be more flexible and efficient. Without gathering data from machines, it is impossible to monitor production progress in real-time. The constantly growing quantity of products and orders impacts delayed shipments and the necessity for improving performance.

MES is a beneficial solution for the production of military equipment due to the provision of greater visibility of the progress of production orders and control over the entire production process. Implementing an MES allows monitoring and validation of materials, tracking of production operations and quality, and identification of areas for improvement.

As the world becomes more connected and businesses strive to become more efficient, the need for advanced manufacturing technology is becoming increasingly important. One of

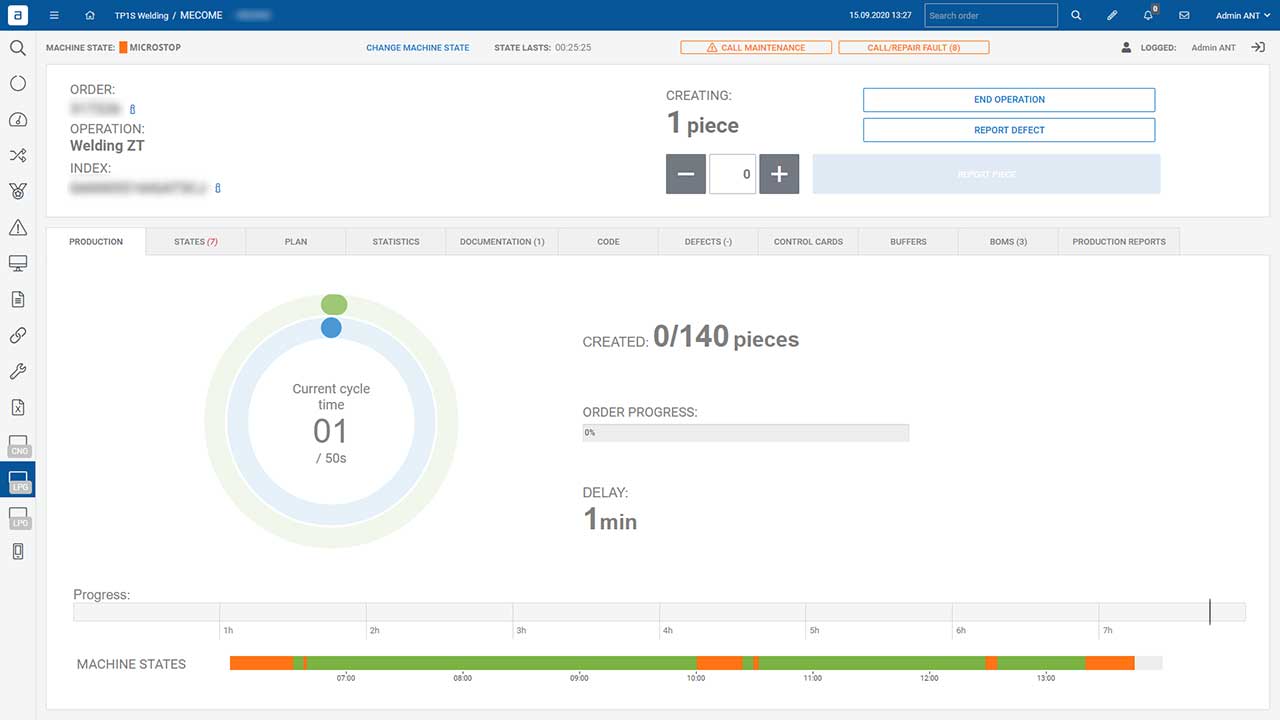

Operator guidance is an essential part of the production process. It primarily ensures that the process is executed following the developed technological guidelines. Step-by-step support

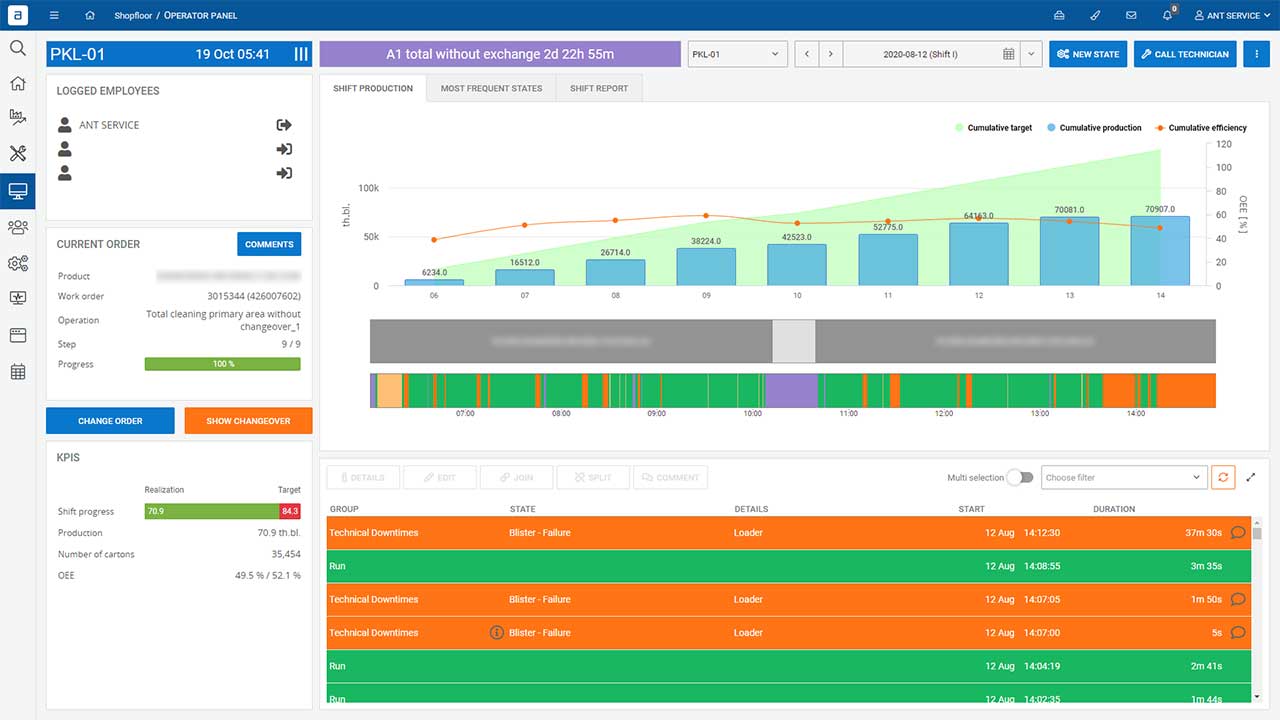

Overall Equipment Effectiveness (OEE) is low due to one or more of the following factors: availability, performance, and quality. Availability may be low due to

By providing your email and clicking the “Sign up” button, you agree to subscribe to our newsletter to receive the latest news and useful insights about manufacturing.

By providing your email and clicking the “Download a catalogue” button, you agree to receive our newsletter.