Advanced Planning & Scheduling System (APS Software)

Your production, perfectly planned.

Accevo APS system is a specialized software tool that works alongside your ERP to plan production, logistics and supply chains in real time.

What is an Advanced Planning and Scheduling (APS) System?

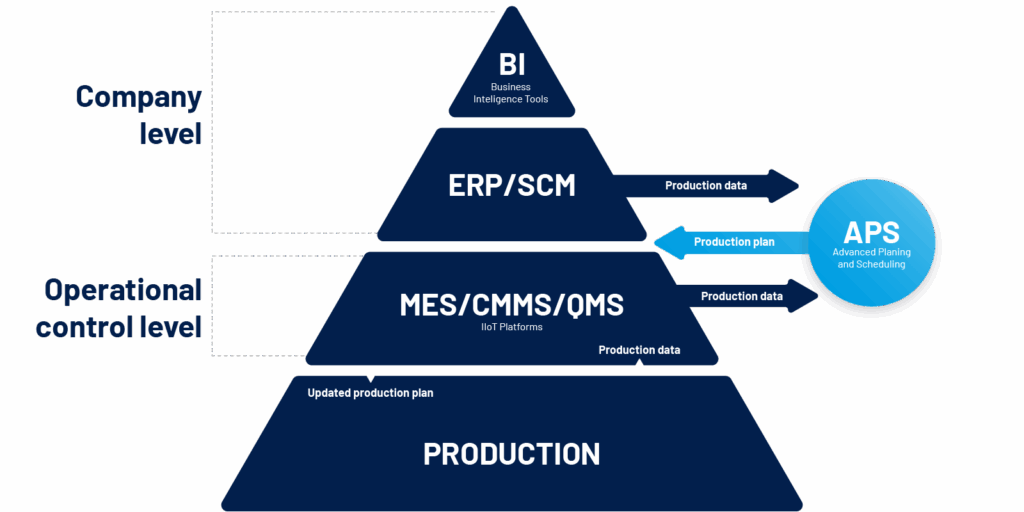

An APS system is software designed to tackle operational planning challenges in production, logistics and supply chain management. It works alongside ERP systems to plan across long, medium and short-term horizons, simulating multiple scenarios in real time to optimize throughput, reduce lead times, manage inventory and improve delivery performance. APS software can help in each industry replacing simple excel files and improving general manufacturing performance.

APS acts as the dynamic link between your high-level planning (ERP/SCM) and the realities on the shop floor. By ingesting real-time production data from ERP systems and sending back optimised production plans, APS transforms static schedules into agile, responsive workflows. In practice, this means you can reduce lead times, improve resource utilisation and keep your strategic goals aligned with what’s actually happening in production.

Indusries Covered

Manufacturing (discrete, process, batch)

Optimises production by reducing bottlenecks and managing capacity and materials.

Automotive

Enables just-in-time scheduling and adapts to complex, changing supply chains.

Food & Beverage

Schedules for freshness, allergen control, and ingredient availability.

Aerospace

Manages long lead times, complex assemblies, and traceability.

Pharmaceutical

Supports compliance, batch tracking, and expiry-based planning.

FMCG

Handles fast-changing demand, short shelf life, and minimises waste.

Textiles

Deals with frequent order changes, colour variants, and machine planning.

Electronics

Supports fast product changes and limited capacity with agile scheduling.

When to even consider APS software?

Consider implementing an APS when your production plans become too complex for spreadsheets or manual methods to handle reliably. If you find yourself juggling multiple machines, materials and staff shifts—and struggling with late orders, bottlenecks or excess stock—an APS brings clarity and control. By running real-time simulations and optimizing every resource against your priorities, you can react quickly to changes in demand, avoid costly downtime and keep deliveries on track.

Intelligent Scheduling

Automatically sequence tasks to make the best use of machines and people, cutting idle time and speeding up delivery.

Solves: chaos from manual job sequencing and unexpected bottlenecks.

Material & Resource Planning

Ensure you have the right parts, tools and staff in place by matching material availability and capacity to your production needs.

Solves: costly stock-outs, over-ordering and unbalanced workloads

Live What-If Scenarios

Run instant simulations of changes—like rush orders or machine breakdowns—to see the impact and adjust your plan before issues arise.

Solves: the inability to foresee disruptions and adapt in time.

Why to choose APS system from Accevo?

Choose Accevo APS because it brings together powerful optimisation, deep MRP and real-time AI in one easy-to-use, web-based planner. You’ll benefit from multi-criteria scheduling that balances priorities like setup times, labour costs and delivery dates, plus built-in forecasting and promise-checks to keep stock lean and customers happy. Our skill-based workforce module and full tool-set management ensure the right people and equipment are always in place. With interactive dashboards, what-if simulations and seamless ERP/CMMS/WMS integration via REST APIs, Accevo APS gives you the control to react instantly to change and drive continuous improvement.

Powerful optimisation engine for faster, smarter scheduling

Deep MRP with built-in forecasting and ATP/CTP checks

Real-time AI learning for ever-more accurate plans

Multi-criteria scheduling (setup times, labour costs, delivery dates)

Skill-based workforce and full tool-set management

Interactive dashboards and instant what-if simulations

Seamless ERP/CMMS/WMS integration via REST APIs

Web-based planner for access anywhere, no client install needed

-

Flexible cost-based optimisation with multiple target criteria

-

End-to-end value-chain planning for seamless workflows

-

Complete Material Requirements Planning to keep stock levels lean

-

Bottleneck-centred scheduling that smooths production flow

-

A foundation for energy-cost planning and AI-powered insights

-

Higher on-time delivery rates and shorter lead times

-

Reduced setup, production and personnel costs

-

Lower work-in-progress levels and better resource utilisation

Features & Modules

- Optimisation Engine

- MRP & ATP/CTP

- Workforce & PRT Scheduling

- Long-Term & Tactical Planning

- Reporting & Control Centre

- Supply-Chain Orchestration

- On-line Feedback from Shop-floor (MES/MOM)

- Real-time Production Progress

- Optimisation Criteria

- AI & Reinforcement Learning

A powerful scheduler that balances multiple goals—such as minimising setup times, cutting labour costs and hitting delivery dates—in real time. Run side-by-side what-if scenarios to compare plans instantly.

Benefits:

Automates trade-off decisions across competing targets

Lets you preview and select the best plan in one click

Deep material planning with lot-sizing rules, hybrid pull-push strategies and live Available-to-Promise checks to confirm delivery feasibility before order acceptance.

Benefits:

Automatically proposes purchase and production orders

Ensures you never overcommit stock or miss a delivery date

Match tasks to people and tools by skill, department or shift. Manage tool-set dependencies and maintenance windows to prevent conflicts.

Benefits:

Guarantees the right staff and equipment are always assigned

Reduces idle time with automated changeover rules

Switch seamlessly between strategic, mid-term and weekly planning horizons. Align your annual master plan with shop-floor execution.

Benefits:

Supports months-ahead capacity and investment decisions

Delivers detailed, week-by-week production schedules

A live dashboard hub with custom-isable charts on utilisation, bottlenecks and on-time performance. Drill down to any timeframe or work centre.

Benefits:

Provides instant visibility into plan impact

Empowers data-driven adjustments on the fly

Orchestrate procurement, production and distribution in one unified schedule. Optimise stock transfers and transport slots across sites.

Benefits:

Ensures materials are in the right place at the right time

Balances loads between plants, warehouses and carriers

The system collects real-time data directly from machines and operators on the shop floor. This online feedback keeps your operations transparent and up to date.

Benefits:

Immediate visibility into current production status

Faster reaction to issues, reducing downtime

Real-time Production Progress

Stay informed with live updates on order progress, machine activity, and operator input. Everything is tracked and visualised as it happens.

Benefits:

Better control over deadlines and delivery schedules

Improved decision-making based on up-to-date information

Optimisation Criteria

Our APS system uses custom-defined rules and constraints to optimise production sequences and resource use. Planning is based on what really matters to your business.

Benefits:

Reduced production time and waste

More efficient use of machines, materials, and labour

A self-learning engine that refines its own rules from historical and live data. Produces ever-more accurate schedules with each update.

Benefits:

Predicts and avoids disruptions before they happen

Continuously improves planning accuracy over time

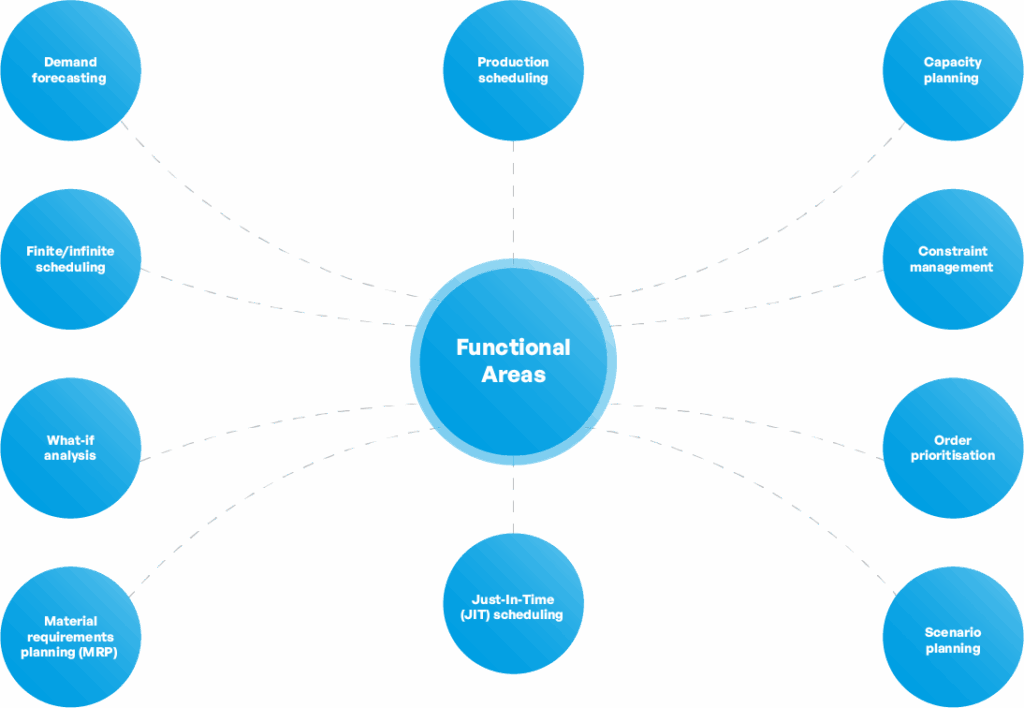

Functional Areas

Our Advanced Planning and Scheduling (APS) system supports a wide range of key functional areas to optimise production and planning processes. It includes tools for demand forecasting, production scheduling, and capacity planning, helping manufacturers respond effectively to changing market needs.

The system also covers material requirements planning (MRP), finite and infinite scheduling, and what-if analysis to evaluate different planning scenarios. With constraint management and order prioritisation, users can handle production limits and ensure timely deliveries. Scenario planning, Just-In-Time (JIT) scheduling, and supply chain synchronisation further enhance coordination across the entire manufacturing network.

Key Technologies

APS systems today harness a range of key technologies to deliver truly responsive and optimised production plans. Finite-capacity scheduling ensures every machine and work centre is loaded within its actual limits, while AI/ML-based optimisation continuously learns from your data to suggest ever-better sequences. Digital twins replicate your shop-floor in a virtual model, enabling risk-free what-if scenarios and faster decision cycles.

Flexible deployment options—cloud, on-premises or hybrid—let you choose the right balance of control and scalability, and real-time data processing keeps schedules up to date as conditions change. Under the hood, powerful heuristic and genetic algorithms tackle complex trade-offs at speed, and constraint programming enforces every rule from tool availability to labour qualifications, so your plans are both ambitious and achievable.

Read further about the technology that Accevo uses.

Challenges In Production Planning

Effective production planning is essential for manufacturing efficiency, yet companies frequently encounter challenges such as limited transparency, rigid systems, scheduling complexities, communication issues, and hidden bottlenecks. These problems lead to inefficiencies, delays, and increased costs. To overcome these challenges, businesses should adopt advanced planning tools, flexible scheduling solutions, improved interdepartmental communication, data-driven analytics, and systematic knowledge management, ensuring better adaptability and competitiveness in production processes.

The top five challenges in production planning are:

Limited transparency across the value-added process

Rigid and outdated planning systems (like Excel)

Difficulty managing daily order scheduling

High communication effort between departments

Lack of visibility into production bottlenecks

Read further in the article Challenges in Production Planning.

Challenges in Production Planning

Effective production planning is crucial for manufacturing companies striving to maintain competitiveness, efficiency, and profitability in a rapidly changing market. Accurate and agile production planning

Integrations & Related Systems

Fully integrated with leading ERP systems such as SAP, Microsoft, Oracle, Infor, and Comarch, our solution ensures smooth data flow and synchronisation across the entire production process. This seamless integration supports efficient planning, execution, and monitoring between ERP, APS, and MES systems.

ERP

- Master and transaction data

- Personnel

- Work centers

- Production resources and tools

- Demands

APS

- Planning and optimization

- Gantt chart

- Order sequencing

- Consideration of constraints

- Analysis

MES

- Confirmations, machine and order state from

MES to Accevo APS - Shopfloor

Compliance with Regulatory & Standards

ISA-95

ISA-95: Integration Standard between Enterprise and Control Systems

ISA-95 is a widely recognised international standard specifically designed to integrate business (enterprise) and manufacturing (control) systems. It provides a structured approach for data exchange between different operational levels, such as management and factory floor operations.

Improves Visibility and Transparency:

By standardising information flows, ISA-95 helps organisations gain clear visibility across the entire manufacturing process. This standard is crucial for identifying bottlenecks, reducing delays, and improving overall operational efficiency.Supports System Interoperability:

Companies employing ISA-95 experience smoother integration of Manufacturing Execution Systems (MES), Enterprise Resource Planning (ERP), and control systems. This interoperability is essential for dynamic production scheduling and real-time decision-making.Enhances Communication:

By standardising terminology and data formats, ISA-95 significantly reduces miscommunications and errors across departments, contributing to more efficient production planning.

Example: A pharmaceutical manufacturer using ISA-95 standards successfully integrates batch production data directly into its ERP system. This integration allows immediate adjustments based on demand forecasts, regulatory requirements, or production anomalies.

ISO 9001

ISO 9001 is an internationally accepted quality management standard focusing on consistent quality delivery, customer satisfaction, and continual process improvement.

Promotes Quality Assurance:

ISO 9001 provides a structured framework to ensure all production processes meet defined quality standards. It directly impacts planning by embedding quality checks into operational routines.Facilitates Risk Management:

By integrating preventive measures and regular audits, ISO 9001 helps identify potential issues in production processes before they escalate, aiding proactive planning and risk reduction.Encourages Continuous Improvement:

Implementing ISO 9001 promotes systematic tracking of performance metrics, enabling continuous improvements in production processes, resource management, and scheduling efficiencies.

Example: An automotive parts manufacturer certified with ISO 9001 systematically reviews production plans and quality metrics. This continuous monitoring ensures prompt action on discrepancies, reduces wastage, and improves production reliability.

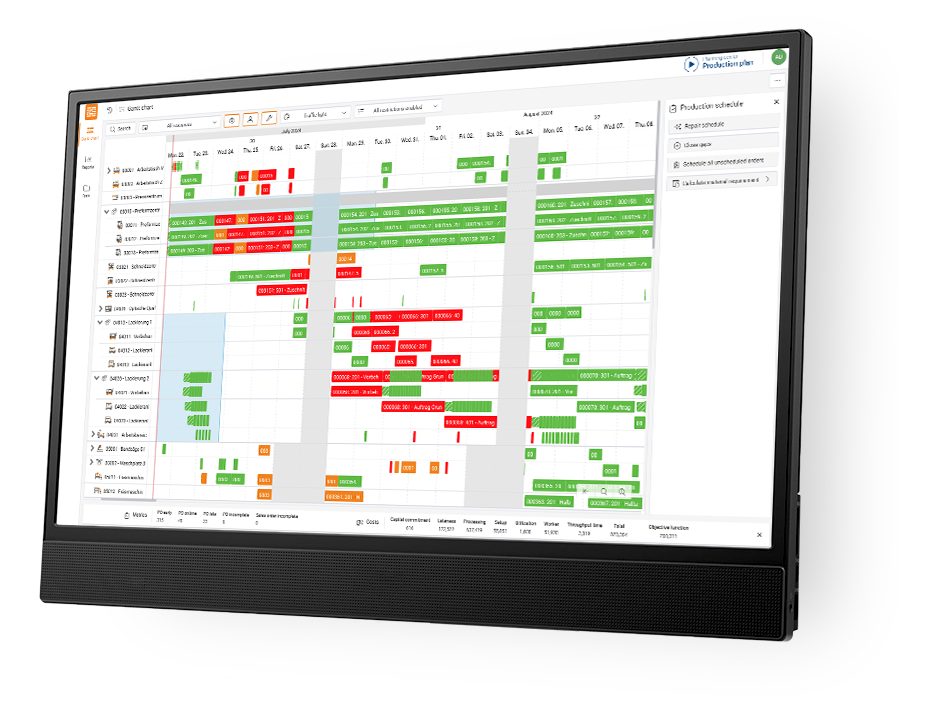

System Presentation

Contact with our Expert

Why to get a demo?

- A 60-minute online meeting with a dedicated specialist presenting a top system from an industry similar to yours

- Live modeling of your production process

- A budget quotation after the meeting

Related articles

How to optimize production plan?

Nowadays, production planning requires particular precision, operating in real time and updating objectives in relation to the current state of the machines. Only on this

Challenges in Production Planning

Effective production planning is crucial for manufacturing companies striving to maintain competitiveness, efficiency, and profitability in a rapidly changing market. Accurate and agile production planning

Production planning in APS as a method for reacting rapidly to process dynamics

The APS system is an advanced tool for planning production and responding to events occurring in real time. Integration of the software with other management

Get insights faster and listen to our AI Podcast about APS software